Cometabolic Bioremediation

On this page:

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

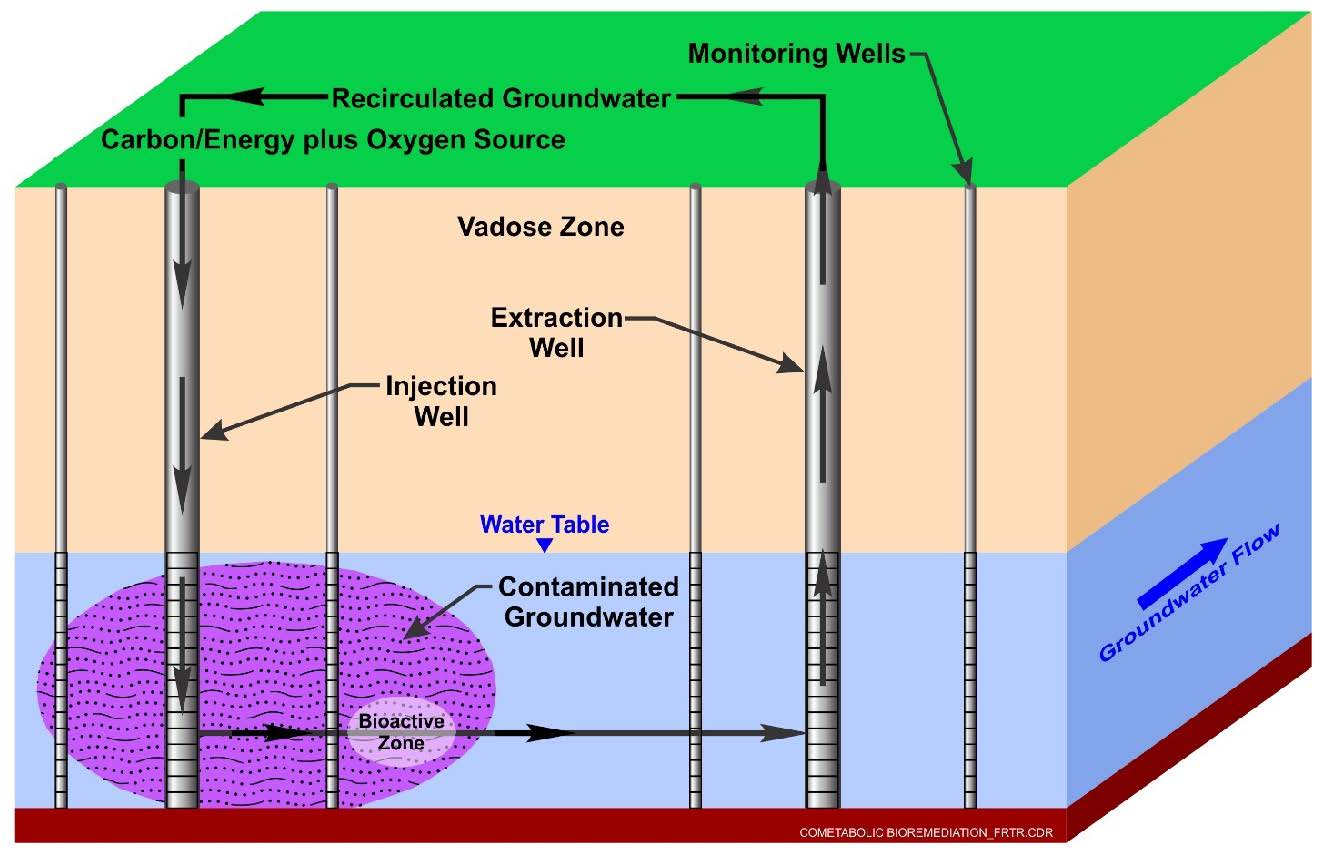

Schematic

This information may be reproduced without restriction as long as the source attribution is included.

Cometabolic Bioremediation

Introduction

Cometabolic bioremediation breaks down a contaminant utilizing an enzyme or cofactor that is produced by microbes oxidizing or reducing other compounds (metabolites) for energy and carbon. It may occur aerobically or anaerobically, but aerobic cometabolism is much more commonly used. It also can occur at low contaminant concentrations, below levels needed to support the growth of the microbe, and reduce contaminants to non-detect levels. Cometabolic bioremediation is typically implemented by injecting gaseous amendments or liquids containing the amendments either in a grid to treat a large portion of the contaminated plume or as a permeable reactive barrier to provide plume containment. Recirculation systems may be employed to achieve more uniform treatment, over a greater volume of the contaminated zone. Pulsed injection strategies may also be used to alternately cycle the cometabolite feed on and off, since contaminant degradation can be inhibited when the cometabolite concentration is too high.

Other Technology Names

Bioremediation by Cometabolism

Cometabolic Aerobic and Anaerobic Bioremediation

Cometabolic Air Sparging

Cometabolic Bioventing

Description

Cometabolic bioremediation occurs when an enzyme or cofactor, produced by a microbe to catalyze the degradation of its metabolic substrate, is also capable of degrading target compounds. Cometabolic bioremediation is designed to target contaminants of concern (COCs) by stimulating or augmenting this biological process.

Cometabolism is different from simultaneous catabolism, where each compound/substrate is degraded concomitantly by different enzymes to release energy. During cometabolism, the fortuitous degradation of the additional compounds does not provide energy or carbon benefits to the microbe. This is an important advantage of cometabolic bioremediation as the biodegradation of a contaminant can be stimulated at low contaminant concentrations, below levels needed to support the growth of the microbe. As a result, cometabolic bioremediation can reduce contaminants to non-detect levels (Hazen, 2010).

Cometabolic bioremediation can occur in both saturated and vadose zones under aerobic or anaerobic conditions. Under aerobic conditions, the contaminant is oxidized by an enzyme or cofactor produced during microbial metabolism of another compound with oxygen. Under anaerobic conditions, the contaminant is reduced by an enzyme or cofactor produced during microbial metabolism of another compound in an environment with little or no oxygen.

A suitable substrate is required to stimulate the appropriate reactions (EPA, 2000; Hazen, 2010). Electron donors that have been used in cometabolic aerobic oxidation include methane, ethane, ethene, propane, butane, iso-butane, aromatic hydrocarbons (such as toluene and phenol), and ammonia. Methanol, glucose, acetate, lactate, sulfate, or pyruvate can serve as substrates during cometabolic anaerobic reduction. Enzymes or cofactors are produced in response to microbial degradation of these substrates. Table 1 summarizes several types of contaminants that can be degraded, common substrates needed, and provides example of the microbes involved and the enzymes produced under different cometabolic biodegradation conditions.

For chlorinated contaminants, aerobic cometabolic bioremediation is generally more efficient and complete than the anaerobic counterpart (SEDRP-ESTCP, 2010). When subsurface conditions are favorable, aerobic cometabolism can result in complete destruction of the contaminants at a relatively low cost. Its primary advantage is that it is not necessary to force the aquifer to become anaerobic, which may be difficult at a site with a high influx of electron acceptors. There are also fewer byproducts of potential concern created than during anaerobic treatment. In anoxic environments, cometabolic dechlorination is considered a ubiquitous but inefficient mechanism for the biodegradation of chlorinated ethenes.

| Cometabolic Biodegradation Conditions | |||||||||

| Aerobic | Aerobic | Aerobic | Anaerobic | Anaerobic | |||||

| Contaminants |

|

|

|

|

|

||||

| Substrates |

|

|

|

|

|

||||

| Microbes |

|

|

|

|

|

||||

| Enzyes (Cofactors) |

|

|

|

|

|

||||

Modified from Hazen (2010)

Like other bioremediation technologies, aerobic cometabolic bioremediation has its limitations (Battelle, 2001; Semprini et al., 2005). First, intermediates produced during cometabolic biodegradation of chlorinated ethenes (notably epoxides) can be toxic to the oxidative microbial community. Second, the cometabolic substrates themselves can inhibit cometabolic biodegradation (as a competitive substrate for the oxygenase enzymes). As such, cometabolic oxidation of chlorinated ethenes may appear to be poorly suited to long-term contaminant remediation under either engineered or natural conditions. To reduce competitive inhibition, pulsing of electron donor or electron acceptor substrate may be needed to allow the alternate use of substrate and contaminant by the microbes.

Techniques for introducing and distributing substrates/cometabolites are similar to those used to distribute amendments for other in situ technologies and are described in detail here. In practice, cometabolic bioremediation can be implemented by circulating fluids containing the cometabolite and oxygen source to create an in situ barrier intercepting a contaminant plume or can be introduced in a grid pattern across a large portion of the plume. In either case, circulation of the amendments and groundwater may occur aboveground or underground. In the aboveground setting, groundwater is brought to the surface to mix with substrates and oxygen and then injected. In the underground setting, groundwater from one zone or aquifer is withdrawn and discharged into another zone or aquifer after mixing with static mixers inside the well. The aquifer becomes a bioactive zone where microbial cometabolism will occur.

Another approach is through the direct injection of air/oxygen and liquid or gaseous cometabolites. A pulsed operation is often adopted to allow optimal microbial growth and contaminant cometabolism to proceed alternately. During pulsed operation, the growth of contaminant degrading microorganisms is promoted at high cometabolite concentrations when injection/circulation is on; when injection/circulation is paused, cometabolite concentrations decrease, and contaminant utilization by the degraders increases due to reduced competition. This process is repeated until the desired reduction in contaminant concentration is achieved.

Cometabolic bioremediation may also incorporate bioaugmentation, which is performed by injection of microbes into the substrate to boost the cometabolic microbial population. Bioaugmentation is usually performed after sufficient substrate has been introduced into the aquifer to create the conditions necessary for microbial growth. The effectiveness and performance of the treatment can be demonstrated via monitoring to show whether the substrate is consumed, how fast the contaminant concentration is reduced, and if microbial growth is stimulated.

Even though cometabolic biodegradation can break down numerous contaminants, field-scale application is still limited (SEDRP-ESTCP, 2010). This is primarily due to the difficulty and high costs of maintaining an aerobic environment and producing the growth substrates of the microbes capable of cometabolizing the contaminants. However, cometabolic bioremediation may be a contributing process that occurs as part of monitored natural attenuation (MNA) of some aerobic plumes.

Development Status and Availability

The following checklist provides a summary of the development and implementation status of cometabolic bioremediation:

☒ At the laboratory/bench scale and shows promise

☒ In pilot studies

☐ At full scale

☒ To remediate an entire site (source and plume) focused on plume

☐ To remediate a source only

☒ As part of a technology train

☒ As the final remedy at multiple sites

☒ To successfully attain cleanup goals in multiple sites

Cometabolic bioremediation is available through the following vendors:

☒ Commercially available nationwide

☐ Commercially available through limited vendors because of licensing or specialized equipment

☒ Research organizations and academia

Applicability

|

Contaminant Class Applicability Rating for Cometabolic Bioremediation (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness, Level of Effectiveness dependent upon specific contaminant and its application/design, I/D Insufficient Data, N/A Not Applicable) |

||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| ● | ● | ● | ● | ♢ | N/A | N/A | ♢ | I/D |

Cometabolic bioremediation has been applied to a variety of contaminants with varying levels of effectiveness, including polycyclic aromatic hydrocarbons (PAHs), explosives such as TNT and RDX, 1,4-dioxane, polychlorinated biphenyls (PCBs), pesticides, methyl tert butyl ether (MTBE), chlorinated alkenes, N-nitrosodimethylamine (NDMA), and halogenated aliphatic and aromatic hydrocarbons (EPA, 2000; Hazen, 2010). Chlorinated contaminants that have been observed to be oxidized cometabolically under aerobic conditions include tetrachloroethene (PCE), trichloroethene (TCE), dichloroethene (DCE), vinyl chloride (VC), trichloroethane (TCA), dichloroethane (DCA), chloroform (CF), and methylene chloride (MC). Cometabolic reductive dechlorination has been observed in the laboratory for tetrachloroethene (PCE), TCE, DCE, VC, DCA, and carbon tetrachloride (CT) under anaerobic conditions.

Cometabolic bioremediation is most effective under engineered conditions, but may also be applied under natural conditions. It is typically used to treat contaminant plumes in the saturated zone, and may also be used to treat the vadose zone where suitable conditions (e.g., sufficient moisture) are present for microbial growth. This technology has been mostly demonstrated and applied for the treatment of chlorinated solvents. In addition, research has been conducted to show that cometabolic bioremediation is a promising treatment for 1,4-dioxane (SERDP, 2016).

Cost

Cost drivers for cometabolic bioremediation include the extent and volume of the treatment zone, aquifer depth, the type and quantity of cometabolite and oxygen required, and the delivery or operation methods needed. As with other in situ technologies that rely on the introduction and distribution of amendments, application costs vary according to site conditions and contaminants, and are described here. Major cost drivers include:

Upfront Costs

- Type of contaminant. It determines the substrate/cometabolite suitable for stimulating the cometabolism and the associated equipment and system. For example, the addition of a flammable cometabolite such as propane will cause a safety concern and add to the complexity and cost of the system as explosion proof equipment would be needed to minimize potential safety incidents in the field.

- Type of treatment. It is not cost effective for nonaqueous phase liquid (NAPL) or areas having high contaminant concentrations (i.e., greater than 10 mg/L [AFRL, 1998]). It is more cost effective for plume control.

- Aquifer hydraulic conductivity and anisotropy. These hydraulic characteristics impact the treatment system configuration and thus the cost of installation.

- Aquifer permeability. For relatively low-permeability settings, more wells and monitoring points will need to be installed (i.e., closer spacing), due to the smaller radius of influence for each injection well. For very low-permeability settings, the technology may not be applicable due to the inability to inject gas or fluids or may require the use of permeability enhancement technologies such as fracturing.

- Aquifer depth and hydraulic properties. A large depth to water results in greater well installation costs. Formations having low conductivities may require more closely spaced wells or points and therefore more wells than those having higher conductivities.

- Because of its more development status, a pilot demonstration of this technology would be necessary at most sites before it is implemented at full scale.

Operation and Maintenance Costs

- Operating, maintenance, and monitoring requirements. Routine system operation and equipment maintenance and the need for monitoring impact the cost of remediation. Monitoring requirements are based on the COCs, expected degradation products, design of the delivery and treatment system, number of monitoring wells, frequency of monitoring, and regulatory requirements.

- Aquifer depth and hydraulic properties. A large depth to water ratio results in higher pumping costs while hydraulic properties affect the spacing and number of treatment wells and thus the associated operating costs.

- Type and amount of cometabolite and air or oxygen source required. These determine the materials and power costs during implementation.

- Performance criteria. Performance criteria can impact the frequency and duration of operation and maintenance, whether pulsing or continuous injection, must be conducted.

- Regulatory criteria. The cost and duration depend on regulatory criteria. A greater remediation timeframe and associated cost are required to achieve stringent criteria (i.e., low cleanup values).

The list above highlights those cost dependencies specific to cometabolic bioremediation and does not consider the dependencies that are general to most bioremediation technologies. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be obtained using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

Cometabolic bioremediation may operate for months to years, but is expected to achieve cleanup goals in a shorter time than MNA or a pump-and-treat system. The duration of treatment may be longer if a source persists or if cometabolic bioremediation is induced under natural conditions. The duration of cometabolic bioremediation is dependent on many factors, including the following conditions.

- Type of contaminant, concentration, and distribution in the plume.

- Source zone conditions (determines the longevity of the plume).

- Concentrations of indigenous microbes capable of the desired cometabolic reaction (determines the time required to stimulate cometabolism and if bioaugmentation is needed).

- Aquifer characteristics (stratification, low-permeability zones, and potential for contaminant rebound) and biogeochemical conditions (whether favorable cometabolic conditions can be maintained).

- Regulatory criteria and rate of cometabolic biodegradation (determines the time required for a certain reduction and to meet applicable criteria).

Due to the difficulty and costs of maintaining an aerobic environment and the growth substrates for the cometabolic microbes, it is desirable to set up realistic performance criteria and optimize the treatment system to minimize the duration of the remedy.

Implementability Considerations

Below are key considerations associated with implementing cometabolic bioremediation. Additional considerations, common to all technologies that rely on the introduction and distribution of amendments can be found here>.

- Types, concentrations, and distribution of COCs impact the substrate/cometabolite needed and design of the delivery system.

- For COCs that require specific microorganisms to biodegrade, the availability of indigenous microbes capable of the desired cometabolic reaction should be determined. Bioaugmentation may be required if they are not present, or if they are present at low concentrations.

- Aquifer properties such as permeability, hydraulic conductivities, anisotropy, stratification, low-permeability zones, and potential for contaminant rebound must be considered when designing the amendment delivery system. At some sites, it may not be possible to inject amendments because the permeability is too low.

- Cometabolic bioremediation generally requires the introduction of one or more gases. Consideration must be given to the design of the injection and distribution system to ensure the design radius of influence is achieved and any potential adverse effects (e.g., vapor intrusion) are mitigated.

- The biogeochemical characteristics present in the aquifer must be assessed. At some sites it may not be possible to maintain necessary conditions for degradation to proceed.

- If the cometabolite concentration is too high, this can be counter-productive, because it would cause the oxygen to become depleted. If oxygen becomes depleted, the cometabolic activity would be quenched.

- Nutrient addition is often required for aerobic cometabolism to proceed.

- Pulsing of substrate and oxygen to reduce competitive inhibition should be considered.

- Column treatability tests and/or pilot tests must be performed before a full-scale application is implemented. Single-well push-pull tests have been used as a component of cometabolic pilot testing. However, it may be necessary to perform push-pull tests at several different locations prior to scaling up over a relatively large area.

- Intermediate products that may inhibit microbial metabolism can also be produced during cometabolic bioremediation. There tend to be fewer byproducts of concern created by aerobic cometabolic degradation compared to anaerobic cometabolic degradation.

- For volatile contaminants, it is difficult to differentiate the mass removal due to biodegradation as opposed to volatilization due to air or oxygen sparging when air or oxygen are injected to maintain aerobic conditions in the formation.

- Safety issues associated with the use of gaseous substrates such as propane and butane must be evaluated.

- Potential of bio-clogging and rehabilitation of injection wells and points. Bio-clogging can occur around injection wells where the substrate and electron acceptor (i.e., some form of oxygen) are introduced into the subsurface. Periodic redevelopment of the injection wells may be required.

Resources

AFRL. IRP, Aerobic Cometabolic In Situ Bioremediation Technology Guidance Manual and Screening Software User's Guide (June 1998) (PDF) (84 pp, 6.00 MB)

This guidance manual presents the principles of aerobic cometabolic in situ bioremediation for chlorinated solvents such as TCE as well as mathematical models used to describe the technology. It also provides a discussion of its applicability and limitations.

Battelle. Use of Cometabolic Air Sparging to Remediate Chloroethene-Contaminated Groundwater Aquifers (July 2001) (PDF) (194 pp, 1.39 MB)

This report presents the results of a demonstration project to evaluate the effectiveness of and costs associated with cometabolic air sparging for removal of chlorinated solvents from groundwater.

EPA. Cometabolic Aerobic and Anaerobic Bioremediation (last updated February 2019)

This EPA CLU-IN website provides an overview of the aerobic and anaerobic cometabolic bioremediation technology, with links to additional resources.

EPA. Engineered Approaches to In Situ Bioremediation of Chlorinated Solvents: Fundamentals and Field Applications (July 2000) (PDF) (144 pp, 2.11 MB)

This report provides an overview of the fundamentals and field applications of in situ bioremediation to remediate chlorinated solvents in contaminated soil and groundwater. The cometabolic mechanism and case studies are presented.

Hazen. Chapter 7, Cometabolic Bioremediation in Handbook of Hydrocarbon and Lipid Microbiology (2010) (PDF) (10 pp, 289 KB)

This chapter provides an overview of cometabolic bioremediation. and is frequently cited by others.

Semprini, Dolan, Hopkins, and McCarty. Development of Effective Aerobic Cometabolic Systems for the In Situ Transformation of Problematic Chlorinated Solvent Mixtures (February 2005)

This report documents a study to develop a cometabolic culture for bioaugmentation and evaluate its performance under laboratory conditions and under in situ conditions in field demonstrations.

SERDP-ESTCP. Evaluation of A Novel Multiple Primary Substrate (MPS) Cometabolic Biosparging Technology for In Situ Bioremediation of 1,4-Dioxane and Chlorinated Solvents in Groundwater

This ESTCP website describes a project being performed to demonstrate a novel multiple primary substrate cometabolic biosparging technology to treat 1,4-dioxane.

SERDP-ESTCP. Evaluation of Branched Hydrocarbons as Stimulants for In Situ Cometabolic Biodegradation of 1,4-Dioxane and Its Associated Co-Contaminants

This webpage describes a project to evaluate isobutane and isobutylene as stimulants for the cometabolic degradation of 1,4-dioxane, 1,1,1-trichloroethane, and its degradation products.

SEDRP-ESTCP. In Situ Remediation of Chlorinated Solvent Plumes (2010)

This monograph covers key aspects of using cometabolic biodegradation to treat chlorinated solvents.

SERDP-ESTCP. Field Demonstration of Propane Biosparging for In Situ Remediation of N-Nitrosodimethylamine in Groundwater (2015) (PDF) (205 pp, 24.2 MB)

This report describes the results of a project to demonstrate and validate the application of propane and oxygen biosparging for the in situ treatment of NDMA-contaminated groundwater to ng/L concentrations.

SERDP-ESTCP. In Situ Bioremediation of 1,4-Dioxane by Methane Oxidizing Bacteria in Coupled Anaerobic-Aerobic Zones (2016) (PDF) (43 pp, 882 KB)

This report describes the results of a bench-scale study to evaluate the cometabolic biodegradation of 1,4-dioxane by methane.