Environmental Dredging

On this page:

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

Schematic

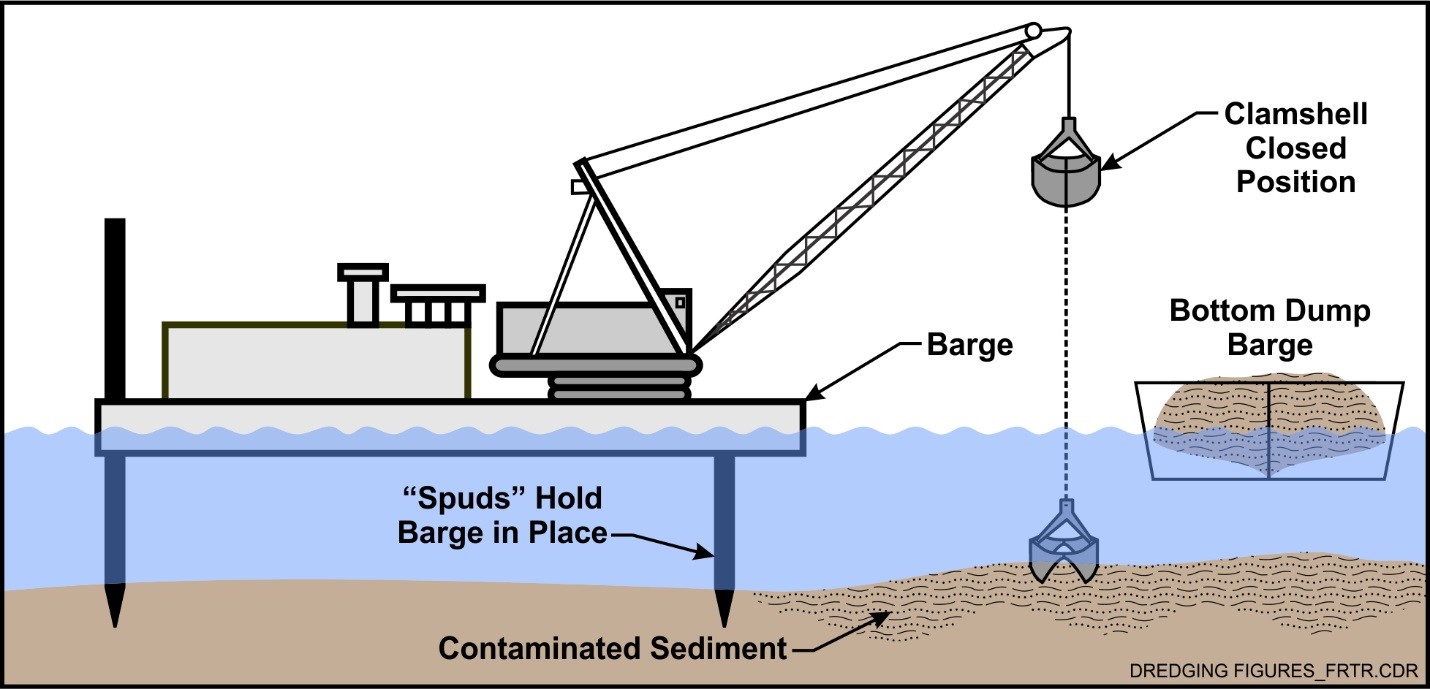

Schematic of Mechanical Dredge and Haul Barge

This information may be reproduced without restriction as long as the source attribution is included.

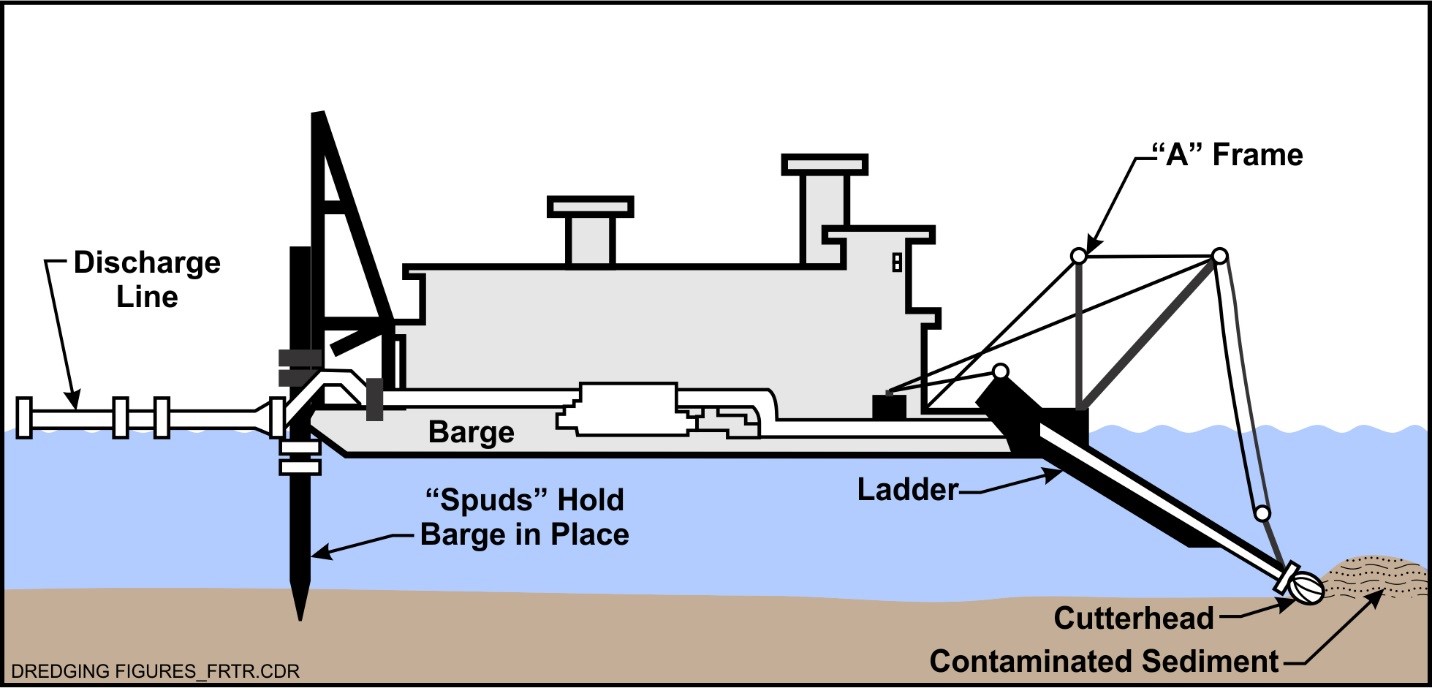

Schematic of Hydraulic Dredge and Pipeline

This information may be reproduced without restriction as long as the source attribution is included.

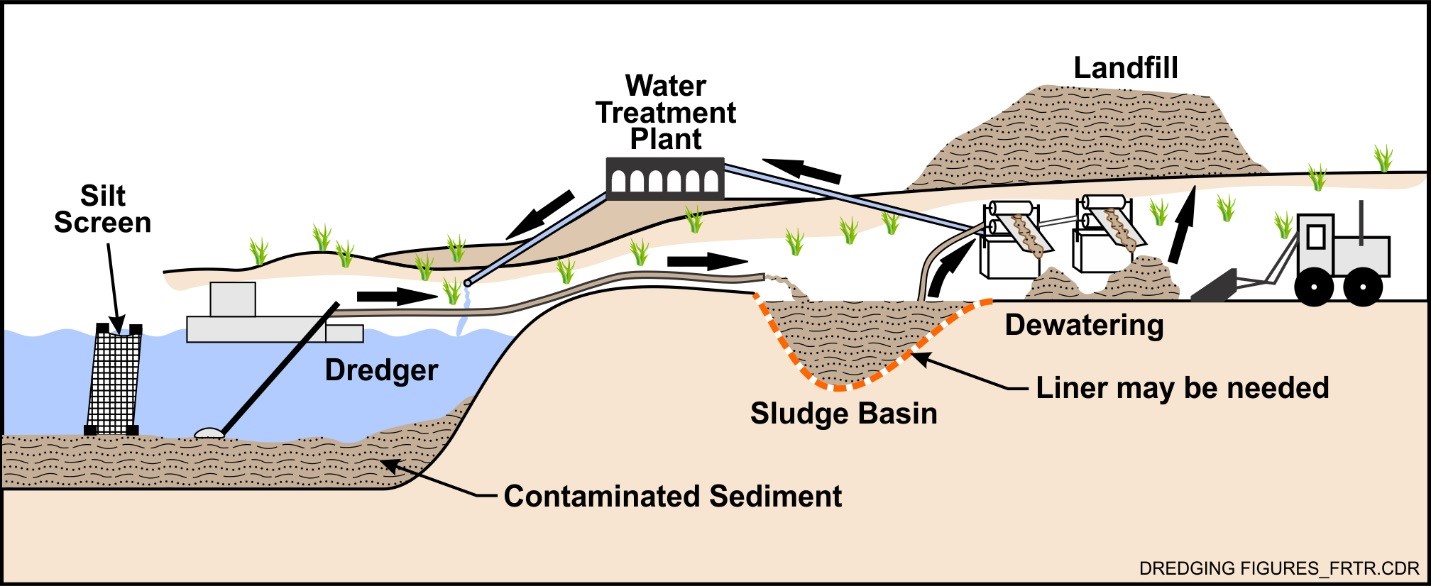

Example of Dredging, Dewatering and Water Treatment Process

This information may be reproduced without restriction as long as the source attribution is included.

Introduction

Environmental dredging is the process where contaminated sediment under water is removed, treated, and/or placed in a new location. Environmental dredging is performed to reduce risk that contaminated sediment and associated porewater pose to human health and the environment.

Other Technology Names

Dredging 1

Description

Environmental dredging reduces ecological and human health risks from exposure to contaminated sediments by removing the source of contamination (i.e., the contaminated sediment). It is effective in removing contaminant mass from near-surface sediments. Contamination in near-surface sediments may become resuspended and transported by natural erosive processes, so that near-surface contaminated sediment may be classified as a contamination "source". Dredging removes this type of source. In some cases, dredging is performed to increase water depths, which may be needed for vessel navigation, flood protection, and other future uses of a waterbody. Even if the primary objective of dredging was not to remove a contamination source, if the sediments contain contaminants, special care is still required to address issues associated with environmental dredging as described herein.

Several issues must be considered during the design and implementation of every environmental dredging project. These include:

- Resuspension of contaminated sediment, which occurs to some degree during dredging operations.

- Release of contaminants from the resuspended sediments and bedded sediments occurs during and immediately subsequent to dredging.

- Residual contaminated sediment is left behind during dredging and results from settling of resuspended sediment.

- Risks are associated with the contaminated sediment, before, during, and after dredging.

Environmental dredging to remove contaminated sediments requires special considerations to manage these impacts during and after dredging. A detailed description of these environmental dredging impacts and assessment and management considerations can be found in The Four Rs of Environmental Dredging: Resuspension, Release, Residual and Risk (United States Corps of Engineers [USACE], 2008).

Site characterization is first performed to understand site conditions and nature and extent of the contaminated sediments. Based on an understanding of the volume of sediment that will require dredging and other site-specific constraints, specific types of dredging equipment can be selected and the dredging design including transport, dewatering, and disposal needs can be identified.

Site Characterization

Comprehensive site characterization must be completed to provide the data needed for the dredge design. Of primary importance, the site should be adequately characterized with respect to the spatial extent of contamination (areal and depth) in order to estimate the volume of sediment that will require removal. Physical, chemical, and other geotechnical properties of the sediments must be determined, which help to identify well-suited removal, transportation, and treatment/disposal methods. The physical environment, including various hydrodynamic conditions (e.g., bathymetry, tides, currents, and waves), general site characteristics (e.g., presence of infrastructure, utilities, in-water structures, and debris), and waterway uses must be known as they will influence the type of dredge that is chosen. Detailed guidance to characterize dredging projects can be found in Dredging and Dredged Material Management (USACE, 2015) and Technical Guidelines for Environmental Dredging of Contaminated Sediment (USACE, 2008).

Selection and Application of Appropriate Dredge Equipment

Dredges are commonly classified as mechanical, hydraulic, or pneumatic, each of which is described below. Hybrid arrangements that use mechanical devices to remove the sediment and mix it with water to create a slurry that is pumped to a dewatering site also are commonly employed.

Mechanical Dredges. Mechanical dredges use digging buckets such as a clamshell suspended by a cable from a crane, an excavator on a fixed arm, or dragline buckets suspended by a cable from a crane. Mechanical dredges remove sediment with a similar density and water content as the in-place material. Some water is added to the sediment because the clamshell and bucket are not always completely full of sediment. Mechanical dredges typically add a water volume that is 0.2 to 0.5 times the in-place sediment volume. Some sediment also is released into the water column as the bucket is raised. Environmental dredging buckets, having specially designed seals, often are employed to minimize release of sediment during dredging.

Hydraulic Dredges. Hydraulic dredges add water to sediment to create a slurry that can be pumped by pipeline to the dewatering site or to a hopper dredge. There are several types of hydraulic dredges that use different methods to loosen sediment and guide the material into a suction pipe. A cutter head dredge has a rotating head that cuts into the sediment. An auger dredge has a horizontal auger that loosens the sediment and pulls it to the center of the dredge where the suction inlet pipe is located. Some hydraulic dredges do not use any cutting device and rely only on suction to remove the sediment. In order to create a slurry and remove sediment, a large amount of water must be added. Typically, the volume of water added is 5 to 10 times the in-place volume of sediment removed.

Pneumatic Dredges. Pneumatic dredges operate with submerged air-actuated pumps. They are designed to entrain very small quantities of water during the removal process (USACE, 2008). These types of dredges are more effective in deep water than shallow water because they need high pressures to operate.

Dredging projects can range in size from a few hundred cubic yards (cy) of sediment to over a million cy, which will affect the type of equipment selected and how it is employed. Typical size ranges include:

- Small - Less than 25,000 cy. Small projects are typically performed with equipment that can be transported by highway trucks. Typical production rates for dredging and processing the dredged materials are 50 to 250 cy per work day, using one shift per day. These projects can be completed in one dredge season.

- Medium - 25,000 to 250,000 cy. Medium projects can also be performed with equipment that can be transported by highway trucks, but may be done with large barge-mounted equipment. Typical production rates for dredging and processing are 200 to 1,000 cy per work day with one shift per day. These projects are generally completed during one or two dredge seasons.

- Large - Greater than 250,000 cy. Large projects can be performed with equipment that can be transported by truck; however, the equipment generally must be partially dis-assembled and re-assembled on site. Large projects are usually more economical if the site is accessible to larger barge-mounted equipment from marine contractors. Typical production rates are 500 to 5,000 cy per day and it is common for dredge contractors to work 24 hours per day. Large projects often require multiple dredge seasons to complete.

Selection of an appropriate method and specific equipment to a large degree will be based on site-specific factors including:

- Dredged material disposal facility requirements

- Transportation of material from dredge site to processing site and to disposal site

- Availability of upland support areas

- Type of sediment and debris

- Water depth

- Type and concentration of contamination

Many dredging projects are located within public water bodies and, therefore, must comply with federal, state and local laws and regulations for work within these water bodies (some may be in ponds on private property). In the United States, dredging work must comply with the requirements of the Clean Water Act (CWA), which requires permits from the USACE and water quality certification from the state where the work is located. In many districts, the USACE uses a joint permit application process in which the USACE coordinates with other state and local agencies to ensure that the work complies with various and numerous permit requirements. For work under the Comprehensive Environmental Response, Compensation and Liability Act (CERCLA) where permits are not required, the work must still meet the substantive requirements of the federal, state and local regulations.

In addition to permits, work on public water bodies may require access agreements from the agency that owns the land within the water body. Likewise, access agreements are required for work on upland property.

Dredged Material Transport to Land

Dredged material can be transported from the barge to land using either mechanical or hydraulic methods. In the majority of projects, sediment removed with mechanical equipment is transported with mechanical methods and sediment removed hydraulically is transported by hydraulic methods. If material is removed by mechanical dredging and must be transported via pipeline, additional water is needed to create a slurry that can be pumped. The sediment slurry dredged with hydraulic equipment behaves more like a liquid than solid material and it is typically not practical to transport slurries with most mechanical equipment; however, there are situations where hybrid systems have been used successfully. One specific design is a hopper dredge, which uses hydraulic suction to remove a sediment slurry and place it into a hopper, where it is allowed to settle out for transport (USACE, 2015).

- Mechanical Transport. Mechanical methods include floating barges, amphibious vehicles, wheeled vehicles, railroads, or conveyors. Barges are the most common method of transport for mechanically-dredged sediment. Hopper barges hold the dredged material in compartments during transport and release the material through doors in the bottom of the compartment. Split-hull barges are a special type of hopper barge that are constructed in two halves which are connected by hinges at the top. One compartment runs the entire length of the barge. At the disposal site, hydraulic cylinders or cables split the two halves apart at the bottom and the material is released. Deck barges simply have flat surfaces to hold equipment or materials. Some deck barges have sideboards to prevent materials from falling into the water. With all mechanical methods, essentially no change in water content occurs during transport. After the dredged material is transported to land, it can be moved using conveyors, railcars, or trucks. For sediment projects, conveyors have been used to move sediment from barges onto shore, between dewatering or other processing equipment, and to spread material at the disposal site.

- Hydraulic Transport. Hydraulic transport is defined as the process of pumping sediment slurry through a pipeline. This process can be an economical method of transporting large volumes of bulk materials, especially when connected directly to a hydraulic dredge. No additional water is required to transport hydraulically-dredged materials; however, it is necessary to add water to create a slurry if the sediment was dredged using a mechanical technique. Transport pipelines can either float on the water surface or be submerged and rest on the bottom of the water body. Steel and high-density polyethylene (HDPE) are the most common pipe materials used in dredging projects, although any pipe material that is compatible with the sediment and water salinity can be used. For long transport distances, booster pumps (to increase the pressure) can be installed along the pipe routes. The maximum distance that hydraulically-dredged material can be transported can range from 2 to 10 miles. Longer distances are theoretically possible, but would require multiple pumping stations and result in an increased likelihood of operational problems.

Dewatering

After sediment removal and transport, the material generally is too wet to be placed directly into a disposal facility. The dredged sediment must be solidified or water must be separated from the sediment particles in order to process the dredged material for disposal, beneficial use, or treatment. There are two types of dewatering methods: passive and mechanical. In addition, solidification is commonly used as a sediment dewatering method. Treatment of the separated water may be required prior to return to the waterbody, and is described in the Dredged Material Processing Technology fact sheet. The need for treatment will depend on level of contaminants and federal and state regulations. Dredged material processing technologies are described in more detail in the Dredged Material Processing Technologies fact sheet.

Dredged Material Transportation and Disposal

After the dredged material is transported to land, it can be moved using conveyors, railcars, or trucks. For sediment projects, conveyors have been used to move sediment from barges onto shore, between dewatering or other processing equipment, and to spread material at the disposal site. Several types of disposal options involve the placement of sediment solids and debris into a containment facility to reduce exposure to the material. This can be done after treatment or after dewatering without treatment. In addition to the disposal of dredged material in a containment facility, dredged material can be used for various purposes. Options include:

- Confined Aquatic Disposal. Contaminated sediment is dredged and placed directly into a subaqueous disposal site without any type of treatment and covered with cap material. The thickness of the cap is site-specific and depends on bioturbation at the disposal site and the need to isolate the contaminated sediments. The disposal site can be made by dredging a pit or by using a natural depression. With this technology, it is not feasible to place impermeable liners in the site or to attempt collection and treatment of porewater. Confined aquatic disposal (CAD) is only practical with mechanical dredging and transport because contaminated dredged material must drop through the water column and land at a predetermined disposal site. Even so, depending on sediment type and degree of consolidation within the bucket, sediment will be released into the water column to some degree and may result in suspension and transport of fine-grain sediment outside of the disposal area. In the case of hydraulic dredging, the slurry that would be forcibly discharged and dispersed into the water column, which is much more likely to spread contamination into the surrounding areas of the disposal site.

The characteristics of the potential CAD site are critical to determine the feasibility of this technology because contaminated sediment would remain under a cap. In general, the site should be classified as non-dispersive, where sediment is in a stable depositional area. Ideally, the CAD site should be in a low-energy location with little potential for cap erosion. However, higher energy sites can be successfully used provided that the design accounts for erosion potential.

CAD sites are most successful when the bottom slope is close to horizontal. The design must consider the potential for erosion due to waves and water currents including those induced by storms. In areas of potential erosion, the upper cap layers should be constructed with coarse-grained material and/or armor stone to resist storm-induced waves and currents. The design should be based on storms with a return interval of 50 to 100 years, and should account for climate change impacts as appropriate. In general, deeper water depths provide a more stable bottom because there are reduced wave effects, much lower or no erosion due to propeller and other marine craft forces, and potentially lower current velocities. However, shallow water areas can be effective when erosion control is considered in the design process. - Nearshore Confined Disposal Facility. The nearshore confined disposal facility (CDF) is a containment technique where dredged material is placed in subaqueous or intertidal areas. The principal difference between nearshore and aquatic disposal is that in the nearshore technology, the disposal area is separated from the surface water by dikes built up above the water level surface (USACE, 2015). This provides more protection of the adjacent surface water since contaminated material is confined. There may be a pond inside the CDF to facilitate placement of a floating hydraulic pipeline, or the area may extend above the water level to provide placement by conventional earthmoving equipment.

Mechanical or hydraulic dredging and mechanical or hydraulic transport can be utilized to remove and transport sediment to a nearshore CDF. If hydraulic transport is used, the area inside the perimeter dikes is usually filled with water and one or more floating pipelines are used to distribute dredged material throughout the site. The ponded area also serves as a detention basin for dewatering the dredged material and for initial gravity settling of the supernatant water that separates from the dredged slurry.

If mechanical transport is utilized, the water inside the dikes may be left in place or removed. If the site is deep enough, it may be possible to leave a small opening in the dike and bring haul barges into the disposal area. As the depth decreases, it is usually necessary to close the dike, remove surface water and completely fill in the "dry" area. - Upland CDF. An upland CDF is similar to a solid waste landfill where dredged material is placed on existing upland areas. The following are three types of disposal facilities that may be utilized: a monofill, designed and built solely for dredged material from one project; a multi-user facility that accepts dredged material from several dredge projects; or a permitted solid waste landfill that can accept dredged material as well as municipal solid waste.

A monofill may be able to accept material by hydraulic transport in a manner similar to a nearshore CDF. The monofill disposal facility consists of perimeter dikes and possibly a bottom liner, leachate collection system, and a water treatment system. Dredged slurry can be discharged directly into the monofill containment area for the duration of the dredging work, then passive dewatering can be performed after the completion of dredging. Once the dredged material has been dewatered, a cover can be placed similar to a conventional landfill.

With a multi-user facility or solid waste landfill, the dredged material must be dewatered prior to disposal. These facilities are designed and operated to transport and place waste material with conventional upland earthmoving equipment and cannot handle slurry material. - Beneficial Use of Dredge Material Upland. The concept of beneficial use of dredge material embraces the idea that dredge material can be used to benefit society and the natural environment. Dredge material can be used to provide environmental and economic benefits in various areas including parks and recreation, strip-mine reclamation, construction/industrial development, and multi-purpose activities. The beneficial use of dredge material simultaneously addresses multiple economic and environmental objectives to provide the greatest public benefit possible. Sediment removed by dredging can be divided into three categories depending on chemical concentrations:

- Sediment with concentrations above criteria for residential areas. Contaminated sediment that is unsuitable for use in residential developments or agriculture can be used in development of commercial sites, for mine reclamation and for fill in parks and other open spaces. These uses generally require that the contaminated material be managed in a manner that contains the contamination in an environmentally-safe manner.

- Sediment with concentrations below criteria for residential use. For some contaminants (copper and zinc for example), the criteria for sediment quality is much lower than the criteria for residential use or for protection of groundwater. In these situations, sediment could be placed in upland projects without restrictions.

- Sediment with concentrations below criteria for open water disposal. This is common for navigational dredge projects, but less common for environmental dredging. However, there may be situations where sediment that has low levels of chemical concentrations needs to be dredged in order to remove sediment with higher levels of contamination. In this case, dredge material that meets the criteria for open water disposal could be reused in aquatic environments without restrictions.

Monitoring during Dredge Activities

A comprehensive monitoring program must be designed and implemented during environmental dredging to measure dredging effectiveness and to ensure compliance with regulatory requirements. Monitoring during dredging operations is performed to evaluate sediment residuals, resuspension, and release and short-term impacts to human health risk and the environment. Elements that are commonly monitored include (USACE, 2008):

- Bathymetry of the dredged area to verify sediment has been removed to the target depth. Bathymetry, combined with global positioning system (GPS) data, provide an accurate method to evaluate removal effectiveness throughout the dredge area. Data collected during dredging are compared to baseline bathymetry data to gauge removal effectiveness and potential for additional dredge passes. Bathymetry data can be obtained using acoustic instruments either directly hung from the vessel or from a boom extending from the vessel. Although single- and multi-beam methods are available, the multi-beam method is generally preferred because it provides more detailed data.

- Contaminant concentration and thickness of the dredged residuals inside and outside of the dredge area to gauge progress toward achieving cleanup levels and to determine the need for additional dredging (or capping). Pre- and post-dredging contaminant concentrations may be compared to understand dredging impacts to the environment. Oftentimes, sediment cores are collected and analyzed to determine thickness and residual concentrations in sediment. Sediment profile imagery (SPI) is an alternative, useful technique that can be rapidly deployed to determine the thickness of dredge-generated residuals (USACE, 2008).

- Total suspended solids (TSS) or turbidity in the dredge area and downstream water column to monitor resuspension and transport of sediment and contaminants and evaluate compliance with state or other standards. Monitoring can be performed by sampling the water column at designated water monitoring stations or by installing and operating continuous real-time measurement probes. TSS is a more accurate and preferred measurement to base site decisions, but analysis generally is performed by a laboratory2. Turbidity is easily measured in real time in the field using either towed or stationary units (USACE, 2008). In some instances, the design and regulatory requirements may require temporary shutdown of dredging operations until turbidity or TSS decrease beneath a specified maximum allowable concentration.

- Air and water quality to monitor release and risk and ensure compliance with state and other standards. Air quality may be monitored in the immediate vicinity of dredge operations if particulates or contaminants absorbed by particulates are a concern. Point of compliance locations, downgradient of the dredging operation, may be required and established as part of the dredge plan. Concentrations of contaminants in the water column may be routinely monitored at these locations. In addition to the concentrations of chemicals of concern, there may be a need to meet general water quality requirements, which may include monitoring for dissolved oxygen, total dissolved solids, and turbidity, among others. Exceedances may result in temporary cessation of operation of the dredge.

- Wind and Current to monitor changes that may occur during dredging operations. A change in either can affect positioning and impact resuspension and release of contaminants. Under certain conditions, it may be necessary to suspend dredging operations if winds and currents exceed acceptable (site-specific) levels or change to an undesirable direction.

Monitoring is also performed to gauge the performance of the dredging contractor and ensure compliance with the dredge design. For instance, dredge production rates and volume of sediment removed may be tracked using bathymetry. Pre- and post-dredge bathymetry data also are critical to confirm that the dredge design depth has been achieved. The efficacy of silt curtains and other barriers to mitigate resuspension and release of contaminants into the water column may also be monitored, if present, to ensure compliance with the dredge design and regulatory requirements.

Post-Dredge Monitoring

A long-term monitoring program is required to ensure that remedial action objectives are achieved and are maintained for a stipulated time after dredging is complete. Post-dredge monitoring may be required to confirm that residual sediment does not pose an adverse risk to the environment and that recontamination of sediment or surface water has not occurred due to settling of contaminated suspended sediments. In addition, if there are potential upgradient sources of contaminated sediment or surface water (e.g., storm water outfall), periodic monitoring of sediment and surface water concentrations and bathymetry may be required. Monitoring may also be necessary to evaluate the progress of recovery of the benthic community. Sediment and porewater may be sampled and analyzed for toxicity, and concentrations of contaminants of concern in organisms may be periodically assessed. If sediment is disposed on site, long-term monitoring of the disposal facility will also be required to ensure the facility is containing the contaminated sediment as designed and complies with all applicable local, state, and federal regulations.

2Innovative sensors are becoming available that allow for real-time TSS data.

Development Status and Availability

The following checklist provides a summary of the development and implementation status of dredging:

☐ At the laboratory/bench scale and shows promise

☐ In pilot studies

☒ At full scale

☒ To remediate an entire site (source and plume)

☐ To remediate a source only

☒ As part of a technology train

☐ As the final remedy at multiple sites

☒ To successfully attain cleanup goals in multiple sites

Sediment dredging is available through the following vendors:

☒ Commercially available nationwide

☐ Commercially available through limited vendors because of licensing or specialized equipment

☐ Research organizations and academia

Applicability

The following table provides a summary of the applicability of dredging.

|

Contaminant Class Applicability Rating for Dredging (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness, ♢ Level of Effectiveness dependent upon specific contaminant and its application/design, I/D Insufficient Data) | ||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| ● | ● | ● | ● | ● | ● | ● | ◐ | ● |

Full-scale applications of dredging are generally not limited by the type of contaminant and in principle can be applied to remove any type of contaminated sediment. However, consideration must be given to environmental impacts that may occur during removal and balanced against the risk of leaving the sediment in place and applying an alternative technology such as sediment capping, monitored natural recovery, or enhanced natural recovery using sediment amendments. Additional measures must be taken to reduce the risk of recontamination of sediment within the treatment area or downstream of where dredging is performed. For instance, if sediment contaminated by fuel is dredged, it would generally be necessary to place absorbent booms and skimmers at the surface to prevent spreading of resulting non-aqueous phase liquid. Many times, silt screens and silt curtains are used to contain sediments contaminated with inorganics, radionuclides and other contaminants to prevent downstream migration and recontamination. If munitions and explosives of concern (MEC) are present, additional requirements may be imposed. For example, the USACE requires that a MEC probability assessment, be completed prior to dredging. If MEC is suspected, the USACE Environmental and Munitions Center of Expertise (EM-CX) must be contacted (256-895-1586 or 256-895-1513) for further guidance.

Cost

Dredging is generally more costly than other sediment remediation technologies such as capping or monitored natural recovery due to the need to remove, transport, and treat the sediments. In addition to treating the sediments, effluent from dewatering operations may require handling, treatment, and disposal under a permit or discharge agreement.

Dredging costs, which vary widely between projects, are influenced by a wide range of factors. The areal extent of the contaminated sediments that must be dredged, the depth of the contaminated sediments, type of dredging method applied, and treatment and/or disposal can all have significant impacts on cost. In addition, dredging tends to be costlier at sites located far from the shoreline and/or from treatment/disposal compared to those that are located adjacent to land and treatment facilities due to the added complexity to transport the contaminated sediments long distances. A cost analysis comparing various combinations of alternative methods is normally developed during the feasibility study phase. Costs must be balanced against the likelihood that the selected dredging remedy will not result in unacceptable adverse environmental impacts including controlling release of contamination to the waterway and minimizing recontamination of the sediment. Examples of major cost drivers are listed below. Additional discussion of dredging costs can be found in guidance documents such as those prepared by the United States Army Corps of Engineers (USACE, 2008 and 2015).

Upfront Costs

- Site characterization and surveys including bathymetry, sediment chemical and geophysical properties, and water quality.

- Areal extent and depth of contaminated sediment.

- Site location in respect to sediment disposal/treatment facilities.

- Type of removal and dredged material transportation methods.

- Many times, dredging projects are subject to "environmental windows," which are time restrictions imposed by federal, state and/or local authorities that address when dredging can be performed. Analysis of environmental dredging projects has shown that these windows result in substantial cost increases to dredging projects (USACE, 2015).

- Location of the contaminated sediment within the waterbody. Sediment in shallow water and in inter-tidal zones is more difficult to dredge because the water depth limits the size of equipment that can be used.

- Type and size of dewatering and treatment facility. Disposal costs for nearshore or upland CDFs varies depending on the ratio of facility costs (i.e., liner, perimeter berms, cover) to the internal volume, which depends on the geometry of the facility.

- Availability of required equipment in proximity to the site. Availability of standby equipment and replacement parts also can influence cost (and time) to complete dredging activities.

- Availability of required infrastructure. The size and location of an upland support area is a major factor in dredged material management cost. For example, when space is limited, mechanical dewatering may be the only option for treating water generated by dredging, which is generally more expensive than gravity drainage in settling basins. In some sites, temporary docks may be required for the project.

Operation and Maintenance Costs

- Areal extent and depth of contaminated sediment and distance from transportation/disposal facility, which impact labor requirements and time to complete dredging operations.

- Sediment water content and concentrations of contaminants of concern. Water separated from sediment generally requires treatment prior to release to the environment.

- Method of sediment removal. The on-water work for hydraulic dredging may be less than the cost for mechanical dredging and required barge transport, but the total project cost may be higher for hydraulic dredging depending on the requirements for water treatment and sediment dewatering.

- Treatment and disposal requirements. A wide range of treatment and dewatering options are available for contaminated sediment, which are selected based on the type of contaminants, concentrations, regulatory requirements, and desired disposal/end use for the sediment. A wide range of chemical, physical, and biological processes can be applied to treat separated water as well as the sediment itself as described in Dredged Material Processing Technologies.

- Contaminant release rates impact the ability to achieve water quality standards. Control of release rates can greatly impact production rates and associated costs (USACE, 2008).

- Monitoring requirements for process control during dredging, including but not limited to bathymetry and surface water quality.

- Long-term monitoring requirements including, but not limited to bathymetry, sediment sampling, porewater sampling, surface water sampling, and monitoring of the benthic community.

- Utilities, including diesel for boats, construction equipment such as bulldozers and backhoes, generators and other equipment.

The list above highlights those cost dependencies specific to phytoremediation and does not consider the dependencies that are general to most in situ remediation technologies. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be obtained using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

The duration of a dredge project is dependent on dredged material processing and material disposal requirements. Production rates are evaluated in terms of dredge time, which is the summation of effective working time and non-effective working time. Effective working time is the time that actual dredging is taking place, while non-effective time is the time when the dredge is operational, but no sediment removal occurs. Non-effective working time is due to various operation and maintenance requirements such as cleaning suction heads, fueling, changing out pipelines, moving the dredge, and other activities necessary to maintain functionality of the operation. The effective working time efficiency (the ratio of effective working time to dredge time) typically is lower for environmental dredging projects, ranging from 55 to 75%, than for commercial dredging projects (70 to 85%) due to water quality management activities, waiting for results of laboratory analyses, sediment treatment, etc. (USACE, 2008). As an example, dredging 3 feet over 1 acre gives a volume of about 4,800 cubic yards. It would take a little over 18 working days to dredge 1 acre with a production rate of 400 cubic yards per day and an effective worktime efficiency of 65%. However, this does not include any additional time to treat and dispose of the dredged sediment and associated water.

Seasonal restrictions (environmental windows), generally set by state agencies, are commonly placed on dredging projects. These requirements limit the length of time that dredging can be performed each year and can substantially extend the total length of the project. Hence, at large sites, a several year period may be required to complete environmental dredging activities.

Implementability Considerations

The following are key considerations associated with implementing dredging:

- Dredging offers several advantages over sediment capping and monitored natural recovery including eliminating the risk of possible chemical migration, no restrictions on future land use are required, and long-term monitoring of the site is not required. However, implementation is usually more complex and costlier than those technologies due to the need for transport and treatment of the removed sediments and dewatering effluent.

- Dredging contaminated and uncontaminated sediment is frequently performed under federal and state permits.

- Most dredge equipment operates best when the thickness of material to be dredged is 3 feet or more. It is not practical to dredge in layers thinner than 1.0 to 1.5 inches.

- Dredging can result in short-term impacts to water quality. During any dredging operation, some sediment becomes resuspended and dispersed. This sediment can then be carried by the current until it settles out of the water column. Sediment porewater released from the dredged sediments may contain contaminants of concern. Therefore, water quality samples should be collected and monitoring performed in adjacent areas during dredging operations.

- It is not possible to remove all contaminated sediment because the work is performed underwater and every dredge leaves some residual material on the bottom. Confirmation sampling should be performed after dredging to demonstrate that the concentrations of chemicals of concern in the remaining sediments are below the cleanup levels.

- Production rates, environmental impacts, costs and availability all must be considered during the design and equipment selection process.

- Performing a pilot study in a portion of the site can result in an optimized full-scale design that reduces cost. Evaluation of various techniques, identification of site-specific challenges, and data on sediment resuspension, recontamination, and release, help to design a more effective full-scale approach.

- Shallow water depths, limited access areas, or wetland environments may potentially require the use of specialized amphibious equipment or small shallow-draft equipment.

- Temporary access roads may be required in order to access the locations alongside water bodies.

- Creative positioning of dredge equipment may be required to achieve access from the water, land, or both water and land. In some circumstances, if dredging is not possible or not an efficient or economical option, then temporary berms or dams may be constructed so that overlying water can be removed and then excavation (removing sediment after overlying water is removed) can be completed. Conventional earth-moving equipment may be used to excavate an area. Depending on the site geography, the extent of these berms or dams could be extensive and costly.

- Environmental windows imposed by state agencies affect the seasonal time that dredging can be performed each year.

- At some sites, it may be possible to apply alternative dredging methods such as installing sheet piles around the contaminated sediment, dewatering the area, and excavating the area, which can improve removal and reduce residuals and resuspension of contaminated sediment. However, the technical feasibility of alternative methods at a specific site and its associated cost must be carefully evaluated.

Resources

EPA. CLU-IN Sediments, Remediation Web Page

This web page provides links to resources on sediment remediation techniques including dredging.

EPA. Superfund Contaminated Sediment Web Page

This web site provides an overview and links for managing contaminated sediment at Superfund sites. It includes a link to the Superfund Sediment Resource Center (SSRC) which is designed to assist on technical issues related to the cleanup of contaminated sediment sites. The site also provides numerous links to resources for sediment remediation including dredging.

EPA. Superfund Contaminated Sediments: Guidance Documents, Fact Sheets and Policies Web Page

This web page contains links to sediment guidance documents, fact sheets and policies and other documents relevant to contaminated sediments, including those addressing dredging.

EPA. Regulations, Guidance, and Additional Ocean Dumping Information Webpage

This web page provides resources pertaining to ocean dumping law, regulations, and treaties and provides national policies, guidelines and reports.

EPA. Contaminated Sediment Remediation Guidance for Hazardous Waste Sites (2005) (PDF) (236 pp, 2.97 MB)

The guidance is designed to assist sediment site managers by providing a thorough overview of methods that can be used to reduce risk caused by contaminated sediment. Chapter 6 addresses dredging and excavation.

EPA. Memorandum: Remediating Contaminated Sediment Sites — Clarification of Several Key Remedial Investigation/Feasibility Study and Risk Management Recommendations, and Updated Contaminated Sediment Technical Advisory Group Operating Procedures (2007) (PDF) (24 pp, 5.75 MB)

This document identifies 11 recommendations based on current best practices for characterizing sediment sites, evaluating remedial alternatives, and selecting and implementing appropriate response actions for remediation of contaminated sediment at CERCLA sites.

EPA. Identifying, Planning, and Financing Beneficial Use Projects Using Dredged Material (2007) (PDF) (114 pp, 1.40 MB)

This "Beneficial Use Planning Manual" presents a framework for identifying, planning, and financing beneficial use projects.

EPA. The Role of the Federal Standard in the Beneficial Use of Dredged Material from U.S. Army Corps of Engineers New and Maintenance 2003-Draft-Engineering-Performance-StandardsNavigation Projects (2015) (PDF) (16 pp, 206 KB)

The document describes a number of recommended actions intended to enhance and facilitate efforts to increase the beneficial use of dredge material.

EPA. Evaluating Environmental Effects of Dredged Material Management Alternatives — A Technical Framework (2004) (PDF) (95 pp, 95 MB)

This document provides guidance to evaluate the environmental acceptability of dredged material management alternatives.

EPA. Draft Engineering Performance Standards Public Review Copy. Appendix: Case studies of Environmental Dredging Projects (2003) (PDF) (16 pp, 2.66 MB)

This document summarizes site details and dredging statistics related to productivity, residuals, and resuspension of contamination for several dredging projects.

Eurofins. Dredged Material Management.

This website provides information related to the analysis of dredged material and provides a variety of references for dredged material evaluation and management.

NAVFAC. Sediments Environmental Restoration

This page provides an overview of sediment sampling, assessment and remediation.

NAVFAC. Implementation Guide for Assessing and Managing Contaminated Sediments at Navy Facilities (2005) (PDF) (29 pp, 20.3 MB)

The document presents guidelines for conducting sediment site assessments and remedial alternative evaluations within the Navy's Environmental Restoration program. It is intended for use by remedial project managers and their technical support staff as step-wise guidance that will apply to most Navy sediment investigations. It includes discussion of the technologies available for remediation of sediments.

Remediation Innovative Technology Seminar (RITS). Sediments Part 2: Establishing Sediment Cleanup Goals (2010) (PDF) (8 pp, 10.3 MB)

Slides from the RITS presentation on establishing criteria, natural recovery, in situ capping, environmental dredging, in situ remediation, and a summary of cleanup alternatives at Navy contaminated sediment sites.

SERDP/ESTCP. Contaminated Sediment Overview Tool

This Web tool provides an overview of the key technical and policy issues for Navy remedial project managers to consider when managing contaminated sediment sites.

SERDP/ESTCP. Sediment Remedy Effectiveness Tool

This page provides an overview of established techniques for sediment remediation of harbors, rivers and lakes including environmental dredging.

U.S. Army Corps of Engineers (USACE). Dredging Operations and Environmental Research Program Web Page

The Dredging Operations and Environmental Research (DOER) Program supports the USACE Operation and Maintenance Navigation Program. Research is designed to balance operational and environmental initiatives and to meet complex economic, engineering, and environmental challenges of dredging and disposal in support of the navigation mission. Research results will provide dredging project managers with technology for cost-effective operation, evaluation of risks associated with management alternatives, and environmental compliance.

USACE. Dredging Operations Technical Support Program Web Page

The Dredging Operations Technical Support Program, known as DOTS, provides direct environmental and engineering technical support to the USACE Operations and Maintenance dredging mission. This Web page provides links to a wide range of references on various related topics.

USACE. Education, Dredging - Keeping Our Underwater Highways Open Web Page

This page contains drawings and descriptions of different types of dredging.

USACE. Evaluation of Dredged Material Proposed for Disposal at Island, Nearshore, or Upland Confined Disposal Facilities — Testing Manual (2003) (PDF) (33 pp, 4.49 MB)

This manual provides technical guidance for evaluation of potential contaminant migration pathways from CDFs. An overview of regulatory considerations is provided.

USACE. Geotextile Tube Structures Guidelines for Contract Specifications (2006) (PDF) (15 pp, 94.9 KB)

These guidelines provide an example set of contract specifications for the construction of geotextile tubes for sediment dewatering.

USACE. The Four Rs of Environmental Dredging: Resuspension, Release, Residual, and Risk (2008) (PDF) (63 pp, 597 KB)

The document summarizes the results of a workshop in which 50 experts discussed major concerns related to environmental dredging including the four Rs - resuspension, release, residuals, and risk.

USACE. Technical Guidelines for Environmental Dredging of Contaminated Sediments (2008) (PDF) (302 pp, 5.25 MB)

This report provides technical guidelines for evaluating environmental dredging as a sediment remedy component.

USACE. Dredging and Dredged Material Management (July 2015) (PDF) (920 pp, 39.0 MB)

This document provides a comprehensive assessment of dredging, including dredging equipment and techniques, treatment strategies and management approaches.

USACE and EPA. Guidance for Performing Tests on Dredged Material Proposed for Ocean Disposal (2016) (PDF) (116 pp, 1.06 MB)

This This guidance document presents the sediment testing guidelines and requirements to obtain a Department of the Army (DA) permit from the New York District (NYD) of the United States Army Corps of Engineers (USACE) for dredging and placement of dredged material at the Historic Area Remediation Site (HARS) in the Atlantic Ocean.

Sometimes generically referred to as dredging. However, dredging also can refer to removal of sediments for a variety of purposes such as maintaining a required water body depth or as part of preparatory work for future bridges and other infrastructure as opposed to removal to address environmental risk. ↩

Sometimes generically referred to as dredging. However, dredging also can refer to removal of sediments for a variety of purposes such as maintaining a required water body depth or as part of preparatory work for future bridges and other infrastructure as opposed to removal to address environmental risk. ↩