Landfarming

On this page:

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

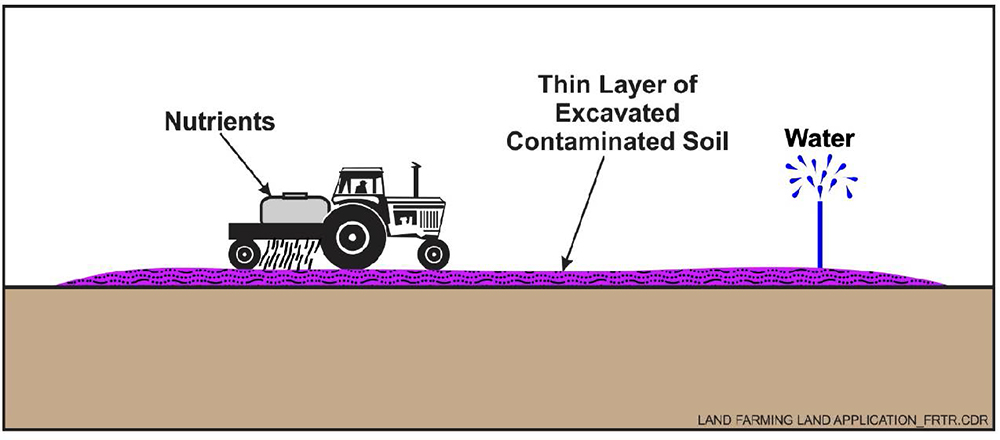

Schematic

This information may be reproduced without restriction as long as the source attribution is included.

Schematic of Landfarming

Introduction

Landfarming is an ex situ, solid-phase biotreatment technology that involves using agricultural practices to promote biodegradation of organic contaminants. Soils or sediments are spread in thin layers across a large open space and potentially mixed into shallow underlying soil, allowing natural processes to degrade and immobilize the contaminants.

Other Technology Names

Solid Phase Biodegradation

Land Application

Land Treatment

Description

Landfarming consists of spreading a thin layer of excavated soil or dredged sediment that contains organic contaminants over a large area to promote attenuation of the contaminants. The spread material is turned periodically using equipment such as a plow or till to expose new surfaces and aerate the matrix. The media, underlying soil, climate, and biological agents interact dynamically as a system to degrade, transform, and immobilize contaminants. Landfarming is different from composting and biopiles in that the clean, uncontaminated soil on which it rests is exposed and potentially mixed into the contaminated material (CPEO, 2002). Landfarming sites must be managed properly to prevent both on-site and off-site issues with contamination. Leachate collection, fugitive dust emission control, adequate monitoring, and environmental safeguards are required. Soil conditions must be monitored to optimize biodegradation as follows:

- Microbial populations in the soil must be tested and monitored to evaluate if the required types are present and in sufficient concentrations to biodegrade the contaminants of concern. In some cases, soil bioaugmented with microorganisms or soil mixed with animal manure must be used to increase the microbial population to produce the best conditions for biodegradation.

- Soil pH should be controlled to produce optimum efficiency. Soil pH should stay close to neutral, generally ranging between 6 and 8. It can be adjusted by adding lime to raise the pH level slightly or adding elemental sulfur to lower it.

- Soil moisture content for optimal biodegradation is between 40 and 85 percent field capacity. Moisture should be added as necessary. When deciding placement of a landfarm, an area without major water buildup should be chosen due to challenges associated with excess water including reduced air permeability, decreased biodegradation rates, and excess water runoff.

- Soil temperature must range between 10 and 45°C for microbial populations to remain active. At cold weather sites where these temperatures are not easily achieved, it may be necessary to construct and maintain greenhouse type structures.

- Soil nutrients should be tested to ensure adequate microbial growth is possible and is not suppressed. The ratio of carbon, nitrogen, and phosphorus needed for microbial populations to thrive ranges from 100:1:0.5 to 100:10:1.

- Soil texture relates to many of the other soil conditions that need to be monitored and maintained. Clay-like soils tend to be bad for landfarming because they exacerbate water retention, they are difficult to aerate, and they hinder nutrient distribution. When working with low permeability soils, bulking agents such as straw can be added to increase aeration and evenly distribute well-blended soil.

- Soil aeration is needed for aerobic biodegradation to occur. Aeration may occur passively if soil is sufficiently permeable and the thickness of the placed layer does not prohibit penetration of air. Mechanical aeration methods such as tilling or plowing are often employed at routine intervals to facilitate aeration and mixing of the soil.

- Water management systems are required to manage stormwater in and around the landfarmed materials. Ditches that intercept water to mitigate runon can be applied (AUEPA, 2014). Runoff can be controlled using lined retention ponds and recycled as needed through the landfarmed materials or treated on or off site, and disposed (AUEPA, 2014).

Development and Implementation Status

The following checklist provides a summary of the development and implementation status of MEC screening technology:

☐At the laboratory/bench scale and shows promise

☐In pilot studies

☒At full scale

☐To remediate an entire site (source and plume)

☒To remediate a source only

☐As part of a technology train

☐As the final remedy at multiple sites

☒To successfully attain cleanup goals in multiple sites

Landfarming design, construction, and operation is available through the following vendors:

☒Commercially available nationwide

☐Commercially available through limited vendors because of licensing or specialized equipment

☐Research organizations and academia

Applicability

|

Contaminant Class Applicability Rating for Landfarming (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness, I/D Insufficient Data, and N/A Not Applicable) | ||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| ● | ◐ | ● | ◐ | ● | ○ | ○ | ◐ | I/D |

Landfarming is used primarily to treat aerobically biodegradable compounds such as fuels and their constituents including nonhalogenated volatile organic compounds (VOCs) and semivolatile organic compounds (SVOCs). Although fuel hydrocarbons have been very successfully degraded with landfarming, their higher molecular weight constituents, such as polycyclic aromatic hydrocarbons (PAHs), degrade more slowly. It also has been used to treat oily sludge, wood-preserving wastes (e.g., pentachlorophenol and creosote), and low levels of explosive residues such as trinitrotoluene (TNT). Chlorinated and nitrate-containing compounds are not effectively degraded via landfarming due to the need for anaerobic conditions.

Cost

Landfarming is a low cost technology used to treat contaminated soil or sediment that has been excavated and requires treatment. The volume of material requiring treatment has a direct impact on cost since the area needed to effectively spread the material will be much greater if a large volume must be treated. Adequate land must be available. Cost also will be greater if a permanent facility and/or greenhouse cover is required. When considering landfarming as an alternative to an in situ technology or other type of ex situ disposal, consideration must be given to the cost to excavate and transport the soil to the treatment facility and transport the treated material to its final destination. These activities and associated costs are ancillary to the construction and operation cost of composting itself and are therefore not considered here. Major cost drivers include:

Upfront Costs

- Sampling and analysis. Samples of the stockpiled soil/sediment need to be collected and analyzed to determine the starting concentrations of the contaminants and the need for amendments (nutrients, water, bulking agents, etc.).

- Treatability testing. Bench-scale testing should be performed to determine the timeframe for remediation and the potential to achieve remedial goals.

- Aerial Footprint. A large aerial footprint is required for landfarming, which is impacted by volume of soil to be treated.

- Equipment. Heavy construction equipment is required to prepare the area, spread the soil or sediment, and periodically till it.

- Emission controls. Landfarming is generally used in cases where vapor collection and treatment are not required but, in cases where it is a requirement, this would have a significant cost impact depending on the type of contaminants being treated and regulatory requirements.

- Construction of the land-treatment cell. Treatment is often performed within a specially designed treatment cell. Construction of the treatment cell may require construction of earthen berms, placement of an impermeable underliner, and a gravel drainage layer. An adjacent, lined water holding pond may also be required.

- Storm water and leachate management. The design and complexity of a storm water collection system is impacted by water treatment requirements. Water that accumulates in the holding pond can usually be returned to the treatment cell (i.e., used for irrigation). In some cases, leachate collection is not required, but in cases where it is a requirement, this would have a significant cost impact.

- Irrigation system. Irrigation requirements are dependent on climate conditions.

Operating Costs

- Labor. Site upkeep requirements include plowing, disking, aerating, and fertilizing.

- Utilities. Utility costs including water and electricity are generally low.

- Sampling and analysis. Confirmatory sampling and analysis of the soil or sediment likely will be required. Costs are dependent on the number of samples required, which is based on regulatory requirements and volume of media treated.

- Emission controls. If granular activated carbon (GAC) is used to treat vapor, additional maintenance will be required and the GAC will periodically need to be replaced and regenerated. As stated above, landfarming is generally used when emission controls are not required.

- Dust control. It may be necessary to irrigate prior to tilling.

- Storm water and leachate management. Cost is impacted by treatment requirements. As stated above, landfarming is generally used when leachate control is not required.

The list above highlights those cost dependencies specific to landfarming and does not consider the dependencies that are general to most remediation technologies. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be obtained using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

Landfarming is a medium- to long-term technology. Operation and maintenance duration for landfarming ranges from 6 months to 5 years. The duration of operation and maintenance is dependent on the following conditions:

- Cleanup goals.

- Concentration and types of contaminants.

- Climate (i.e., temperature, winds, and rain).

- Degradation rates.

- Tilling frequency.

The efficacy and speed of biodegradability is dependent on the nature of the contaminants. The more complex the chemical structure of the contaminant, the longer it takes for the landfarming process to be effective. Low molecular weight non-volatile contaminants are generally more quickly biodegraded where heavier contaminants take longer in the landfarming process. Biotreatability studies can be performed to estimate biodegradation rates.

Implementability Considerations

The following factors may limit the applicability and effectiveness of the process:

- Very high contaminant concentrations may be toxic to microorganisms.

- Soil temperature must be between 10° and 45°C for effective microbial degradation of contaminants.

- Soil moisture must be between 40 and 80 percent of field capacity.

- Soil pH must be close to neutral (between 6 and 8).

- Soil type and texture must allow aeration and conditions listed above to achieve effective results. Excessive rainfall or wind speeds are capable of causing erosion of soil.

- The method is not suitable for treating highly hazardous or toxic contaminants.

- A large amount of space is required.

- Runoff collection facilities must be constructed and monitored.

- Fine particulates in the soil may cause dust generation when tilling dry soil. Dust control may be necessary.

- Topography, erosion, climate, soil stratigraphy, and permeability of the soil must be evaluated to determine the optimum design of the facility.

- Heavy metals are not treated by this method and can be toxic to microorganisms.

- Debris greater than 60 mm in diameter typically must be removed prior to processing.

- Some volatile contaminants tend to evaporate during aeration instead of being biodegraded. Local regulatory requirements may mandate that these constituents be trapped using a greenhouse or plastic cover and treated to avoid release to the atmosphere. The treatments of these emissions are regulated differently in each state and specific requirements need to be investigated.

- Landfarming is not applicable for "land ban" contaminants listed in state and/or Federal regulations or for contaminants that are not readily biodegraded.

Resources

EPA. Landfarming Website

This site provides a summary of landfarming for cleanup of petroleum constituents.

EPA. Bioremediation Using the Land Treatment Concept (1993)

This document provides an overview of land treatment technologies including the basic processes and design and operation considerations.

EPA. Aerobic Biodegradation of Oily Wastes: A Field Guidance Book for Federal On-scene Coordinators (2003)

This field guide on aerobic land treatments (landfarming) of oily wastes was developed for EPA Region 6's Oil Program. It provides an overview of factors to be considered and studied when determining if landfarming is a viable option, key points in the process design, and information on efficient management of aerobic land treatments.

EPA. How to Evaluate Alternative Cleanup Technologies for Underground Storage Tank Sites: A Guide for Corrective Action Plan Reviewers: Chapter 5 Landfarming (2004)

This chapter provides a discussion of landfarming for petroleum remediation, operation principles, system design, advantages and disadvantages.

UFGS 02 54 20 Bioremediation of Soils Using Landfarming Systems

This guidance document provides design, operation, and monitoring requirements for landfarming of soils that contain environmental contaminants of concern.