Techniques to Distribute Amendments in an Aquifer

On this page:

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

Schematic

This information may be reproduced without restriction as long as the source attribution is included.

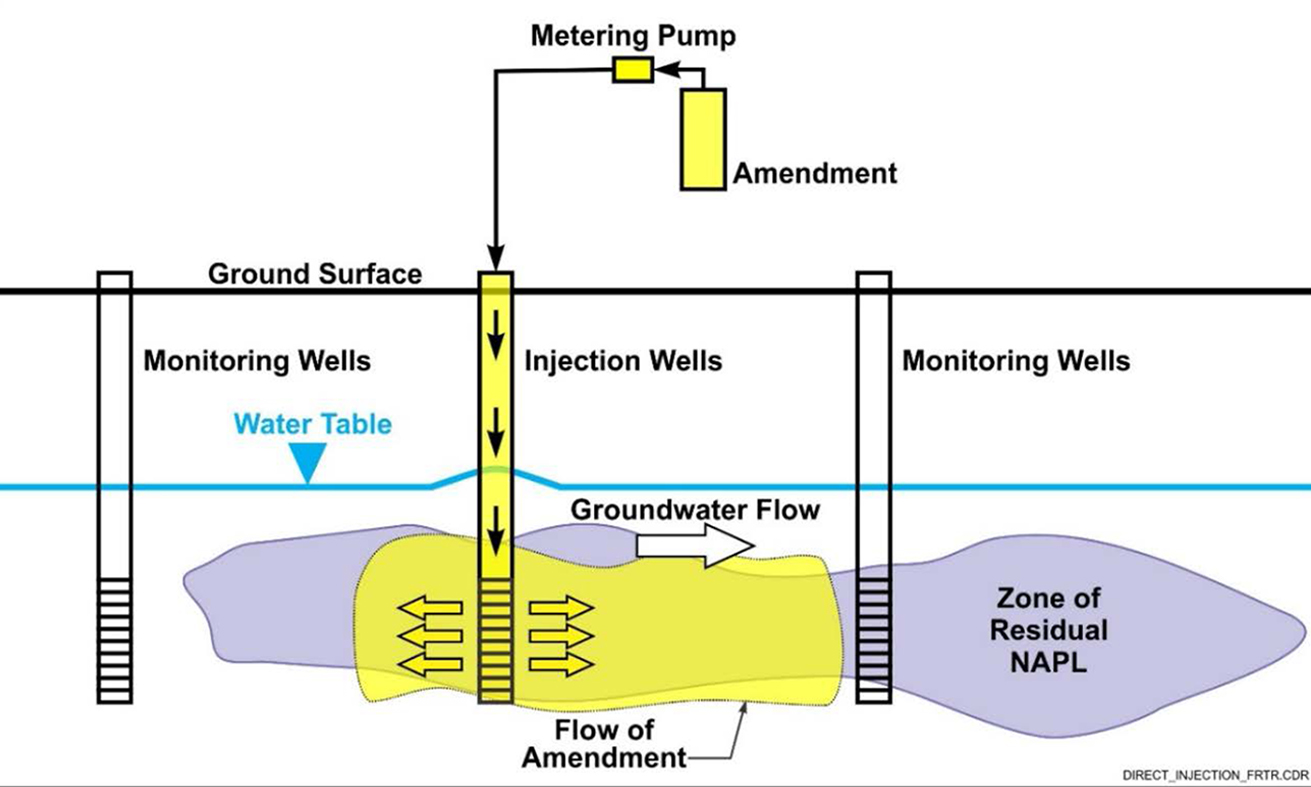

Direct Injection of Amendments

This information may be reproduced without restriction as long as the source attribution is included.

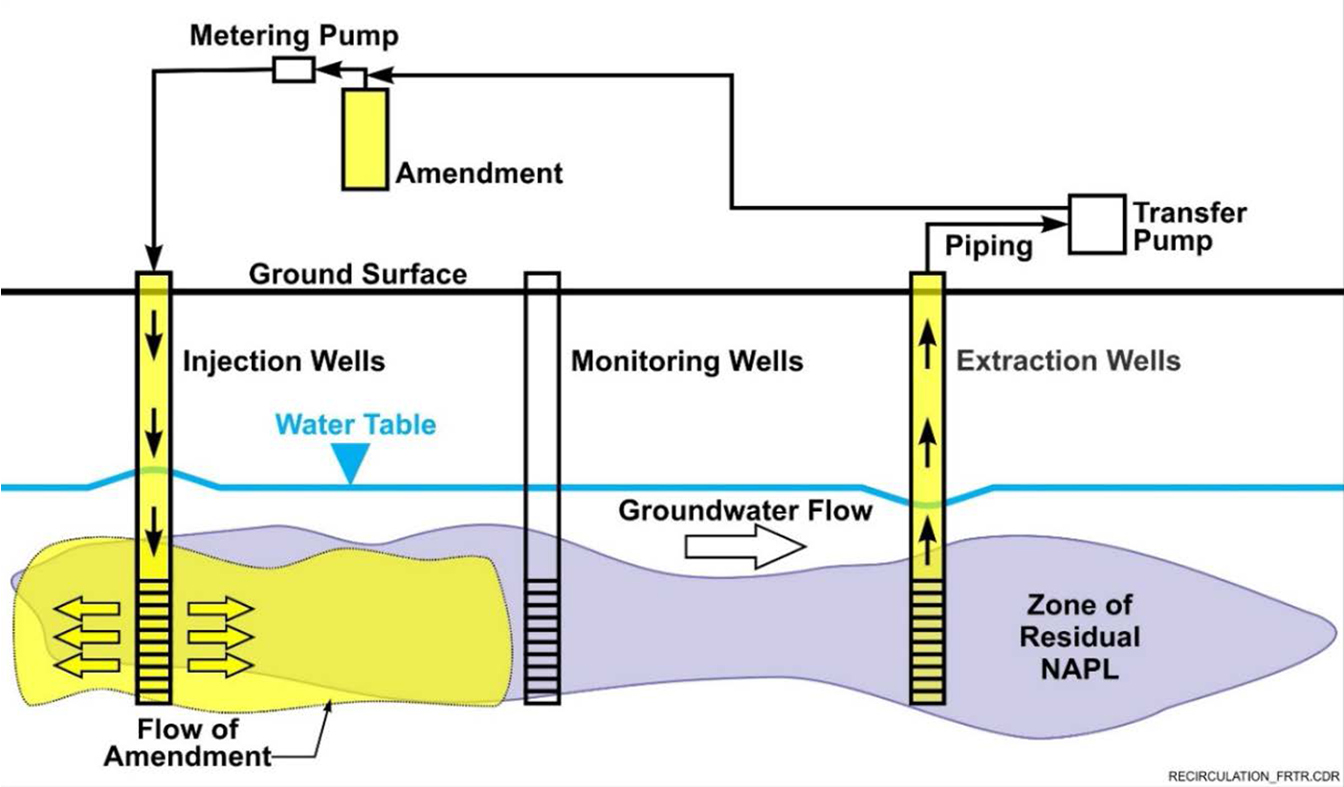

Groundwater Recirculation with Amendments

Introduction

Many remediation technologies, including in situ chemical oxidation (ISCO), in situ chemical reduction (ISCR), enhanced reductive dichlorination (ERD), and anaerobic oxidation, rely on the introduction of amendments into the aquifer. A common challenge encountered during application of these technologies is the ability to achieve adequate distribution and contact between the reagents, substrates, and contaminants of concern. A number of techniques are available to facilitate distribution of amendments, and ensure contact with the contaminants of concern.

Other Technology Names

Amendment Injection

Amendment Delivery

Amendment Addition

Description

In situ remediation amendments can be divided into the following groups (SERDP & ESTCP, 2017):

- Water soluble compounds dissolve easily and can migrate over long distances, so tend to be preferable when treating aquifers consisting of more homogeneous coarser-grained soils with higher groundwater velocities. They include electron donors such as alcohols, ethyl lactate or sugars; chemical oxidants such as sodium permanganate or sodium persulfate; or chemical reductants such as ferrous sulfate or sodium sulfide; anaerobic electron acceptors such as magnesium sulfate; buffers such as sodium carbonate; and others. Because water soluble compounds are easily transported from the treatment area, they may need to be replenished frequently to maintain the necessary conditions for the remedy to proceed. ISCO reagents tend to be soluble and react relatively quickly in the aquifer, although of the three most commonly used liquid oxidants (hydrogen peroxide, permanganate, and sodium persulfate), hydrogen peroxide reacts the fastest and permanganate the slowest.

- Slow release compounds tend to have low solubility limits and greater viscosities than the water soluble compounds, making them more difficult to emplace in the aquifer. However, because they are less soluble, they persist much longer and tend to be preferable for aquifers involving the following applications: 1) direct push applications with smaller spacings that will not rely on groundwater flow for distribution; 2) slower groundwater velocities; or 3) very high groundwater velocities that can quickly flush out amendments. Common slow release amendments used for ERD include various oils and oil-in-water emulsions. Proprietary oil emulsions are produced by a number of vendors1 (e.g., EOS®, EVO®, HRC®). For ISCO, permanganate candles have been developed by embedding permanganate within a lattice of paraffin wax. When placed in wells, groundwater slowly dissolves the permanganate to create a solution that flows in the direction of groundwater.

- Suspensions of insoluble particles, which include micro-scale or nano-scale zero valent iron (ZVI). Suspensions of particles are most frequently used in ISCR applications and are often applied under pressure using a fracturing technique.

A wide range of techniques can be applied to introduce and distribute amendments depending on the physical and chemical properties of the amendments that are used as well as the characteristics of the area to be treated (i.e., source area or dissolved phase plume) and remedial objectives (e.g., mass destruction, prevent further plume migration). Injection methods can be active, passive, or a combination of the two (SERDP & ESTCP, 2017). Active methods rely on the continuous addition of amendments during the treatment period (e.g., recirculation), whereas passive methods introduce the amendments in a short period, and then provide time for them to migrate further into the aquifer under ambient conditions (SERDP & ESTCP, 2017). Combined approaches, sometimes referred to as semi-passive, can consist of the forced introduction and recirculation of an amendment, followed by a period of time to allow it to distribute and react under ambient conditions, after which, additional amendment and/or forced recirculation is applied (SERDP & ESTCP, 2017).

Several common delivery techniques that can be used to introduce amendments include (NAVFAC, 2014):

- Direct Injection. Amendments are injected directly into the subsurface in a specified volume of water from an external source, displacing groundwater corresponding to the volume of reagent injected. Direct push methods are well-suited for permeable materials because there tends to be sufficiently interconnected pore space to permit the distribution of the amendment throughout the treatment zone. In low permeability materials, such as silt and clay, the radius of influence (ROI) may be limited and high pressure may develop, which can create preferential pathways for which amendments and groundwater can travel to the surface. In addition, there is a greater likelihood to displace contaminated groundwater from the treatment area compared to recirculation approaches (NAVFAC, 2013). The direct injection process can be repeated for multiple rounds of amendment applications, which can be accomplished using permanent wells or by direct push methods, depending on the hydrogeology, number of injection events, and associated costs. An economy of scale can be realized for the installation of permanent wells as the number of injection events increases. Direct injection is the most common technique to introduce suspensions of insoluble particles. It is commonly used to perform source area and hot spot treatment using an injection grid approach or to install a permeable reactive barrier downgradient of the source area.

- Recirculation. Groundwater is extracted from one or more extraction wells, amended with reagents and then reinjected into different injection wells. Alternatively, groundwater circulation wells may be used, which allows recirculation of groundwater inside the wells without pumping the groundwater to the surface. Recirculation and mixing of amendments into groundwater is commonly performed using permanent injection and extraction wells, although a combination of direct push points and permanent wells can be used. Recirculation of amended groundwater can be used to treat large areas such as the source zone or dissolved-phase plume and facilitates distribution and mixing of amendments in the aquifer (NAVFAC, 2013; ESTCP, 2012). Recirculation systems are designed to minimize displacement of contaminated groundwater compared to direct injection systems by creating flow pathways from the injection locations to the extraction locations.

- Push-Pull. A set volume of groundwater is extracted, amended with reagents above ground and then reinjected into the subsurface through the same well from which it was extracted. Push-pull facilitates aboveground mixing of amendments and contaminants ensuring good contact. It is often used to perform pilot tests. However, it does have a greater potential to push groundwater from the treatment area.

- Pneumatic and hydraulic fracturing. Pneumatic fracturing is used to form fractures with controlled bursts of high-pressure gas, while hydraulic fracturing is performed by injecting a biodegradable slurry comprised of a viscosifier (e.g., guar gum) dissolved in water, which is polymerized using an additive to create a viscous gel. An enzyme is added to the gel to break it down shortly after injection. "Proppants", which are solid granular materials (usually sand) that fill the fractures and maintain them open, can be used with both fracturing methods. Fracturing is most applicable to low permeability formations, clay soils, glacial tills, bedrock, etc. in which the injection ROI is limited.

One or more of these approaches may be used at a site. In addition, there are many variations of these techniques depending on site-specific conditions and remedial goals. Approaches also may be combined to facilitate introduction and distribution of amendments. For instance, hydraulic fracturing can be combined with recirculation to create additional flow pathways to facilitate distribution as well as improve hydraulic control. As another example, at an ISCO project performed at a Navy facility located in California, groundwater was extracted using permanent wells, amended with persulfate, and reinjected into direct push points advanced to target discrete intervals where high levels of contaminants were present (NAVFAC, 2014).

A number of innovative amendment delivery techniques are being developed and tested to enhance introduction and distribution of amendments. Several of these include:

- Shear-thinning fluids can be used with various amendments to increase flowability and enhance their distribution in the aquifer. Shear-thinning fluids have been used for this purpose for ISCO, ISCR, and bioremediation applications. A more novel application is to add the shear-thinning fluids to an amendment solution to improve distribution of amendments at sites with heterogeneous lithology consisting of intermixed low- and high-permeability units. Shear-thinning fluids are non-Newtonian, meaning that their viscosities exhibit a temporary drop when the applied shear rate is increased. Because of this property, there is a more significant viscosity reduction to the fluid flowing through the lower permeability zones relative to the viscosity reduction of the fluid flowing in higher permeability zones. Therefore, preferential flow through the more permeable material is significantly reduced while the flow into the lower permeability material is increased. In addition, a transverse pressure gradient is created, which produces a cross-flow gradient of fluid from the higher to lower permeability units. Common shear-thinning fluids used in remediation projects include water soluble polymers such as xanthan and guar gums. A demonstration performed at Joint Base Lewis-McChord (ESTCP, 2014) found that the application of 800 mg/L of xanthan gum combined with 1,000 mg/L of ethyl lactate (electron donor) in water increased the distribution of the electron donor in the aquifer from 49% to 69% and effectively treated the trichloroethylene (TCE) using ERD in lithology comprised of glacial outwash and till with varying silt content. The study concluded that shear-thinning fluids are most effective when the permeabilities of the low and high units differ by less than two orders of magnitude.

- Jet injection has been developed to improve distribution of amendments into low permeability materials such as clays. It employs a high pressure stream of water to erode and carve out pathways into which a slurry of proppants (e.g., sand) and reactants such as ZVI are introduced. The method relies on the application of a very high pressure, which is generated by above ground pumps and pushed through proprietary tooling introduced into boreholes.

- Directional wells contain long lengths of screen that are installed either horizontally or at various angles in the formation. There are two situations in which they are advantageous. One is where there are substantial aboveground structures that prevent the installation of vertical wells. The second is when there exists a relatively thin layer of vertical contamination (NAVFAC, 2014). Directional wells may not be well suited when the vertical extent of contamination is large, since multiple wells would be required at the same location, and they are very expensive to install. One of the primary challenges of using a directional well is to ensure that amendments are distributed evenly across the screened interval, which can be difficult since lithologic properties, such as permeability and conductivity, can vary across the horizontal screen interval and create preferential injection pathways.

- Electrokinetics is the process of applying an electrical current to the subsurface through electrodes that have been installed in the aquifer to create movement of ions with the objective of facilitating the removal of contaminants through a variety of processes. This technology is being used to promote distribution of ISCO and ERD amendments into low permeability clay and silt zones.

Understanding the characteristics of the subsurface is important when applying in situ technologies that require the introduction of amendments. Distribution tends to be easier in sandy, more permeable and homogeneous aquifers. It is difficult to obtain adequate distribution of amendments in fine sand, silt and clayey materials and in heterogeneous aquifers containing multiple discrete lithologic units, although the innovative methods described above may help to facilitate distribution. In less permeable aquifers, injection points must be spaced close together. Geochemical conditions including hardness, total organic carbon, dissolved organic carbon, pH, buffering capacity, and contaminant concentration must be known to design the amendment distribution system and determine appropriate mass, concentration, and flowrate of amendments. The concentration of amendments used depends on these factors as well as the type of delivery approach applied. Some vendors have developed dosing design tools to optimize an appropriate dosage based on site-specific conditions for the amendments they sell.

Development Status and Availability

The following checklist provides a summary of the development and implementation status of techniques to distribute liquid amendments in an aquifer:

☐At the laboratory/bench scale and shows promise

☒ In pilot studies

☒ At full scale

☒ To remediate an entire site (source and plume)

☐ To remediate a source only

☒ As part of a technology train

☒ As the final remedy at multiple sites

☒ To successfully attain cleanup goals in multiple sites

Techniques to distribute liquid amendments in an aquifer are available through the following vendors:

☒Commercially available nationwide

☒Commercially available through limited vendors because of licensing or specialized equipment2

☐Research organizations and academia

Applicability

|

Contaminant Class Applicability Rating for Techniques to Distribute Liquid Amendments in an Aquifer (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness, I/D Insufficient Data, N/A Not Applicable) | ||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| ● | ● | ● | ● | ◐ | ◐ | ◐ | ◐ | I/D |

Techniques used to introduce and distribute amendments are applicable to a variety of technologies. As such, a wide range of compounds can be treated, based on the type of technology that is applied. Volatile organic compounds (VOCs) and semi-volatile organic compounds (SVOCs) have been well documented to be treated by technologies such as ISCO, ERD, and ISCR. Light non-aqueous phase liquids such as hydrocarbon fuels can be treated to some extent by technologies such as ISCO; however, the reaction rate is limited by the time it takes for the LNAPL to dissolve into groundwater, although various methods, such as heating, can facilitate dissolution.

Remedial systems can be designed to add amendments to treat inorganic metals, radionuclides, and explosive constituents. Effectiveness is based on the specific contaminants and the types of amendments that are used. Amendments can be used to stimulate biodegradation processes that can directly degrade compounds like trinitrotoluene (TNT), or can change the oxidation-reduction potential and pH of the aquifer, which can promote sequestration of these compounds. For instance, ISCR has been used to remediate energetics and immobilize inorganics including chromium (VI), arsenic, and uranium (ITRC, 2011).

A range of site- and technology-specific factors impact the applicability of technologies that rely on the introduction of amendments. These primarily include the chemical and physical properties of the amendments; site lithology; and groundwater and contaminant velocities. Each site must be evaluated to ensure that a sufficient mass and concentration of an amendment is introduced at appropriate locations to ensure that sufficient contact is achieved with the target contaminants of concern.

Cost

Technologies that rely on the introduction of amendments can be cost-effective if properly designed and applied. In designing an injection strategy, a common goal is to reduce overall project cost by optimizing the number of injection points/wells, amendment volumes, and events. For example, the use of large volumes of a soluble amendment may minimize the number of injection points, but the amendment itself may have a higher purchase cost and have higher operation and maintenance costs due to excessive lowering of pH and/or biofouling in the wells or formation. Similar to many in situ remediation technologies, the most critical cost factors are associated with the nature and extent of contamination (i.e., size and depth of the treatment area) and number of injection points/wells required. As with all in situ technologies, application costs vary according to site conditions and contaminants. Major cost drivers include:

Upfront Costs

- Treatment area. Size of treatment area and treatment approach (e.g., reactive barrier, direct injection grid, recirculation). As the treatment area and number of required injection events increase, recirculation can be become more cost effective versus batch injection events (assuming higher permeability geology), but there will be a significant upfront capital cost and space and security considerations.

- Types and quantities of amendments required. Dictated by the technology being applied and the contaminant mass to be treated and other site-specific factors.

- Number of injection points/wells required. Dictated by the contaminant mass to be treated, site hydrogeologic conditions, and strategy. For instance, fewer wells or points likely would be required to install a reactive barrier to prevent plume migration compared to a network of points installed in a grid to treat the source area.

- Injection well/point design. Direct push points tend to be less expensive than vertical permanent wells, while horizontal wells tend to be more expensive and require careful design and operation. Permanent wells can be re-used during subsequent injection events, which can become more cost effective as the number of required injection events increase.

- Equipment. Determined by the application method and duration of each injection event. Permeability enhancement techniques (e.g., hydraulic fracturing) require the need for additional equipment.

- Labor. The size of the site, the type of technology and distribution method applied, availability of existing infrastructure (e.g., utilities), the need to install temporary points versus permanent wells, and aboveground versus subsurface distribution pipes all have significant impacts on the cost of labor at a site.

Operation and Maintenance Costs

- Frequency of reapplication, and volume and type of amendments.

- Labor. The duration of each injection event, the type of technology implemented, the method of application and monitoring requirements impact labor costs.

- Utilities.

- Fouling. Precipitates and biological fouling can necessitate surging, flushing, heating and/or the use of various chemicals to periodically remove scale. The level of fouling is based on the time the equipment is in use as well as the amount of time between applications.

- Monitoring requirements between injection events.

The list above highlights those cost dependencies specific to techniques to distribute liquid amendments in an aquifer and does not consider the dependencies that are general to most in situ remediation technologies. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be developed using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

Full-scale implementation will vary depending on the specific technology that is being applied and the technique that is used to introduce and distribute the amendments into the aquifer. Each application can range from days (direct injection, small area) to months (recirculation, large area). Additional applications of amendments may be required over several years. Active remediation, during which amendments must be re-introduced, is expected to take 1 to 5 years; however, long-term monitoring may be required for a longer interval after all applications of amendments have been completed. Treatment timeframes can be decades for more complex remediation sites involving significant source area contaminant mass, large plumes, and/or high initial dissolved phase contaminant concentrations. Primary factors that influence the duration of technologies that rely on the introduction of amendments include:

- Remedial goals and remedial action objectives.

- Treatment methodology (i.e., source area treatment, dissolved plume treatment, containment).

- Presence of light non-aqueous phase liquid or dense non-aqueous phase liquid and initial concentrations of contaminants.

- Reactivity, sequestration, and/or consumption of the injected amendments by the formation.

- Number of injection events required.

- Ability to achieve uniform distribution and sustained concentrations of amendments in the aquifer.

Implementability Considerations

The following are key considerations associated with introducing and distributing amendments in the aquifer:

- It is particularly important to have a thorough understanding of the conceptual site model (CSM) when designing and applying in situ treatment technologies. A detailed understanding of geochemical and lithologic characteristics of the site, flow and mass transport, and transformation and sorption of contaminants and the proposed amendments is required to ensure adequate distribution and contact of the amendments with contaminants (e.g., matching of contaminant distribution to soil lithology and potential preferential flow paths). High resolution site characterization can be considered to achieve a better understanding of site conditions and improve the design and application of the remedy.

- An injection plan detailing the design of the amendment delivery system and monitoring requirements should be developed for every site. The plan should include appropriate treatment milestones, contingencies for conceivable deviations based on uncertainties and unknowns present in the CSM, health and safety concerns, and any regulatory issues.

- Dosing of reagents and substrates must consider the pore volume of aquifer to be treated, concentration, and frequency of introductions into the aquifer. Insufficient loading rates increase the probability that the amendments will not be adequately delivered or distributed, which can result in inadequate treatment or a higher number of required injection events. For example, dichloroethene and vinyl chloride require stronger reducing conditions than TCE for reductive dechlorination to occur, which could result in "stall conditions" if adequate amendment volume cannot be delivered. Conversely, excess amendments can create undesirable changes in the aquifer (i.e., plugging the formation with insoluble reaction products, uncontrolled fermentation reactions that can generate excessive methane or reduce the pH of the aquifer to a level not optimum for ERD, etc.), which can compromise the efficacy of the remedy.

- Direct injection is typically limited to a depth of about 100 ft beneath ground surface (bgs) (NAVFAC, 2014). Locations are easily changed in the field, allowing the remedy to be optimized in real time to enhance mixing and distribution of amendments. However, costs can be greater if multiple applications are required, and in some cases smearing of formation material across the injection screen can prevent or reduce flow.

- Coarse materials (e.g., caliche) can prevent direct push methods from adequately penetrating the formation and achieving the necessary design depth.

- Permanent wells may result in overall lower cost if multiple injection events are required. They do not have depth limitations, and clogging of the screen is less likely than for direct push points if designed properly. However, when using permanent wells, it is more difficult to make field changes during application due to the need to remobilize a formal drill rig to install additional wells. Wells must be designed and constructed to handle the expected injection pressure, which can be high in certain instances based on lithology, depth, and other site-specific factors.

- Preferential flow paths due to heterogeneous lithology or subsurface structures and utility corridors can severely influence amendment distribution and result in pockets of untreated contaminant mass. Recirculation can be better at distributing amendment and delivering them faster than direct injection.

- Biofouling can clog the well screen, adjacent sand pack, and/or adjacent formation at the injection or recirculation wells. To prevent or mitigate biofouling, typical approaches include pulsed injection, well flushing with clean water to remove substrate, and the application of non-oxidizing biocides to control growth in the immediate vicinity of the well and reduce clogging of nutrient and water injection wells (ESTCP, 2005).

- Amendment distribution becomes more difficult and may be infeasible for lower permeability clay, highly layered, or heterogeneous subsurface environments. Higher injection pressures or permeability enhancement techniques (e.g., hydraulic or pneumatic fracturing) may be necessary to improve distribution of amendments for these conditions.

- The top-down approach generally achieves more uniform distribution of amendments than the bottom-up approach. The bottom-up approach can result in a pyramid-like flow distribution, which places a greater volume of fluids at deeper intervals. However, the bottom-up approach can be appropriate when greater concentrations of contaminants are at the deepest interval, and/or a large dose of amendments is needed to treat contaminants and limit matrix diffusion releases from an aquitard.

- An underground injection control permit may be required. Requirements vary from state to state. In general, this requirement is waived for food-grade substrates (e.g., vegetable oil) (NAVFAC, 2014).

- For ERD applications, vendors have developed oil-water emulsion formulations that include both aqueous and slow-release compounds. The water soluble compounds are degraded rapidly, generating the conditions necessary for reductive dechlorination to occur, while the slow release compounds provide a long-term source of electron donor for the dechlorinating microbial population, which increases the time required between applications of the substrate.

- Daylighting (surfacing) of groundwater and/or amendments is a common problem when the permeability of the aquifer is too low to accept the design volume of amendment at the applied injection flowrate. This problem is exacerbated when high pressures are used and/or reaction of an amendment generates gas (e.g., hydrogen peroxide).

Resources

ESTCP White Paper. A Review of Biofouling Controls for Enhanced In Situ Bioremediation of Groundwater (2005) (PDF) (55 pp, 765 KB)

This white paper provides an overview of the causes of biofouling and various approaches for mitigation.

ESTCP Tool: Emulsion Design Tool Kit (February 2009)

The Emulsion Design Tool is a spreadsheet-based tool developed to guide the design of emulsified oil distribution systems for enhancing bioremediation of contaminants in groundwater. Also available is a presentation on implementing the tool as well as a User's Guide detailing necessary calculations and the effects of different design parameters on contact efficiency.

ESTCP Report: Addendum to Principles and Practices Manual – Loading Rates and Impacts of Substrate Delivery for Enhanced Anaerobic Bioremediation, ESTCP Project ER-200627 (January 2010) (PDF) (39 pp, 473 KB)

This document describes methods to determine an appropriate substrate loading rate and an effective distribution method for the various substrate types commonly applied for enhanced in situ anaerobic bioremediation.

ESTCP Book: Delivery and Mixing in the Subsurface. Processes and Design Principles for In Situ Remediation (2012)

This book provides a basis for designing and operating in situ remediation systems to ensure adequate delivery and mixing of amendments, groundwater, and contaminants of concern.

ESTCP Report. Enhanced Amendment Delivery to Low Permeability Zones for Chlorinated Solvent Source Area Bioremediation (September 2014) (PDF) (202 pp, 11.4 MB)

This project demonstrated the use of shear-thinning fluid-based technology to improve treatment within low-permeability (low k) zones of heterogeneous subsurface environments.

ITRC. 2011. Permeable Reactive Barrier: Technology Update (2011) (PDF) (234 pp, 7.58 MB)

This guidance provides information pertaining to the application of applying amendments such as ZVI and other reductants to create permeable reactive barriers.

NAVFAC. Technical Report: Best Practices for Injection and Distribution of Amendments (March 2013) (PDF) (81 pp, 2.62 MB)

The objective of this document is to present current "best practices" for introducing liquid- and solid-phase amendments into aquifers and improve the likelihood that these amendments are adequately distributed. Best practices and lessons learned through evaluation of past applications of these technologies are provided.

SERDP & ESTCP. ER Wiki: Injection and Distribution of Liquid Amendments in Groundwater Provides principles and practices to achieve distribution of liquid amendments in the aquifer.

-

The FRTR does not endorse any particular type of amendment. ↩

-

The FRTR does not endorse any particular type of amendment. ↩

-

Some techniques, such as jet injection or electrokinetics, are very specialized and only available from a limited number of vendors. ↩

-

Some techniques, such as jet injection or electrokinetics, are very specialized and only available from a limited number of vendors. ↩