Enhanced Aerobic Bioremediation

On this page:

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

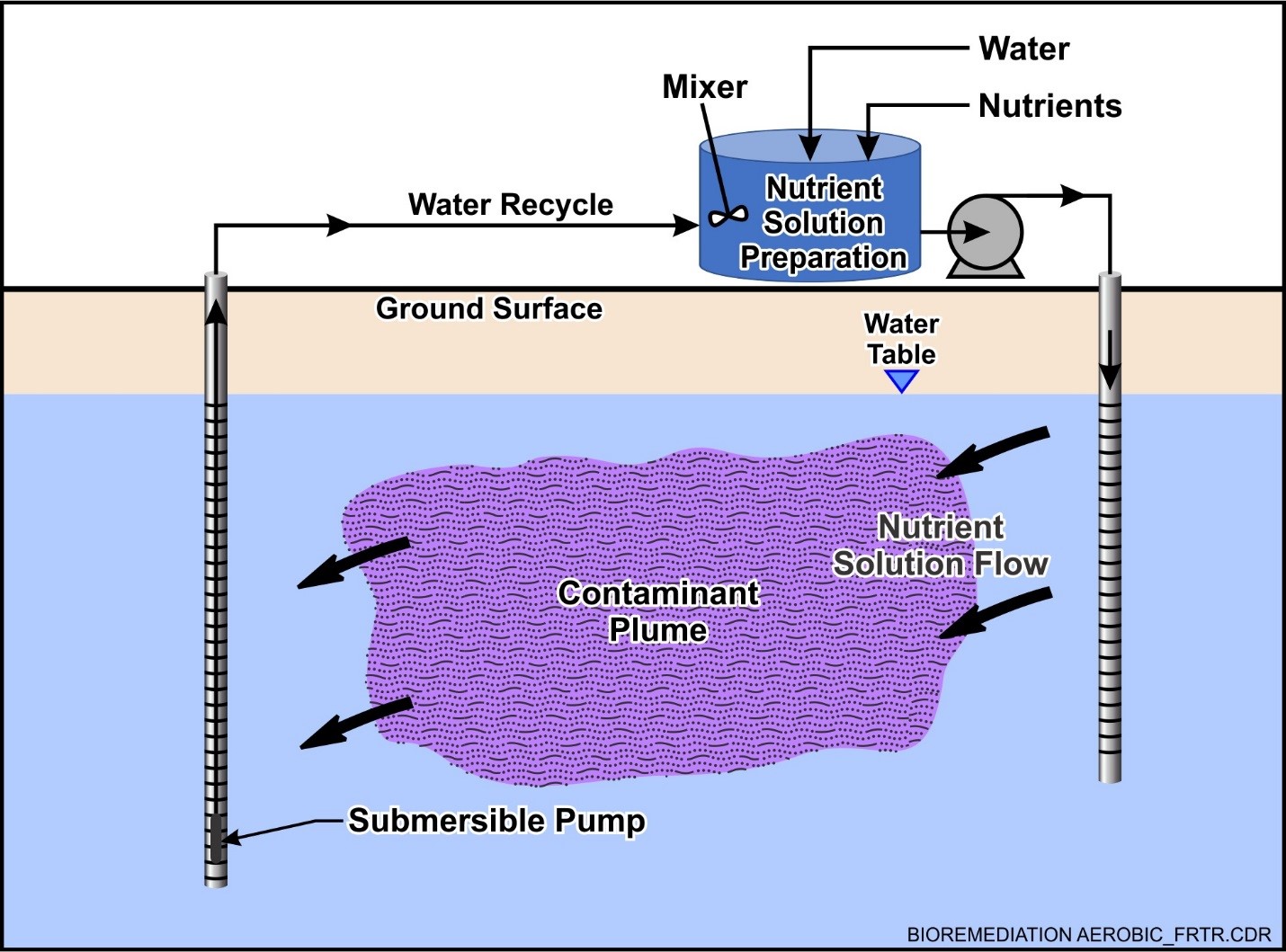

Schematic

Conceptual Diagram of Enhanced Aerobic Bioremediation in Groundwater

Introduction

Enhanced aerobic bioremediation is the process of stimulating indigenous oxygen-dependent microorganisms in soil and groundwater to create the conditions necessary for the microorganisms to biotransform contaminants of concern (COCs) to innocuous byproducts. Aerobic bioremediation of petroleum hydrocarbons and other organic compounds, such as some fuel oxygenates (e.g., methyl tertiary-butyl ether [MTBE]), has been demonstrated and applied at sites for decades. This profile focuses on applying aerobic bioremediation in the saturated zone using direct metabolic processes. Cometabolic bioremediation and bioremediation of vadose zone soils using bioventing and biopiles are addressed in separate technology profiles.

Other Technology Names

Packed Column Air Stripping

Biosparging

Biostimulation

Description

Enhanced aerobic bioremediation relies on effective delivery of oxygen to the subsurface to maintain an aerobic environment to facilitate biodegradation of the COCs. Aerobic microorganisms utilize the oxygen and the organic contaminants as part of their metabolic processes and convert the contaminant into carbon dioxide, water, and microbial cell mass (EPA, 2001; EPA 2004).

Common strategies for delivering oxygen to the saturated zone include the following: sparging air or oxygen into the aquifer; directly injecting oxygen release compounds (ORCs); or recirculating groundwater with above-ground addition of an oxygen-releasing amendment such as hydrogen peroxide. These strategies are characterized below. In some cases, the delivery of amendment enhancements (such as nutrients) may coincide with the oxygen delivery strategy, or they may be passively introduced via wells or trenches. Permits may be required to inject air, oxygen, or ORCs into the subsurface. Detailed discussion of techniques for introducing and optimizing distribution of amendments can be found here.

- Biosparging: Biosparging promotes biodegradation of contaminants by using lower flow rates than are used in air sparging to enhance biodegradation while minimizing volatilization. As such, biosparging entails the direct injection of air or pure oxygen at low flow rates into injection wells screened below the contaminated zone. A series of existing vertical injection wells are often alternately sparged so that dissolved oxygen levels are more efficiently increased over larger areas (ITRC, 2009a). In practice, some degree of volatilization occurs regardless of flow rate (NAVFAC, 2001a). Advantages of biosparging include: residual non-aqueous phase liquid (NAPL) mass immobilized within the capillary/smear zone and shallow saturated zone can be treated; no removal, treatment, storage or discharge of groundwater is required; there is a minimal requirement for vapor capture and treatment due to low air injection rate; treatment times are generally short (6 months to 2 years under favorable conditions); and there is a minimal disturbance to site operations and availability of readily available equipment (NAVFAC, 2003).

- Oxygen Releasing Compounds (ORCs): ORCs are a class of solid compounds 1 that release oxygen into groundwater through the hydration of calcium and magnesium peroxides. They can sometimes be used to stimulate bioremediation in the unsaturated zone if adequately hydrated, but more commonly are used to treat contaminated groundwater or saturated soil (EPA, 2004). Typical means for introducing ORCs to the aquifer include adding the solid material directly into drilled boreholes, mixing the solid material into open soil excavations, creating and injecting a slurry into direct-push borings, and suspending socks filled with solid material in groundwater monitoring wells. The longevity of ORCs usually lasts between 4 to 12 months per application.

- Hydrogen Peroxide: Often in enhanced bioremediation, groundwater recirculation 2 is used to provide mixing and contact between the oxygen source, nutrients, contaminant(s), and microorganisms, thereby enhancing the rate of microbial biodegradation of target contaminants. Dilute solutions of hydrogen peroxide can be added to extracted groundwater and re-injected into the aquifer to serve as the oxygen source. Typically, the hydrogen peroxide-amended groundwater is injected into wells located in or near suspected source areas or downgradient of the source area for targeted plume treatment. The objective of the groundwater recirculation system is to provide continuous distribution of the hydroxide peroxide because of its rapid decomposition or dilution of the generated oxygen with groundwater flow and recharge.

- Ozone Injections: Ozone has a greater oxidation potential in comparison to hydrogen peroxide and is 10 times more soluble in water than pure oxygen with a decomposition rate of approximately 20 minutes from the time it is introduced into the aquifer. It can be introduced using recirculation systems or directly injected into points or wells similar to methods used for biosparging air or pure oxygen. In some instances, ozone is injected in combination with hydrogen peroxide to generate a more aggressive free radical that promotes in situ chemical oxidation along with bioremediation (ITRC, 2005).

Enhanced aerobic bioremediation is commonly used to treat dissolved phase plumes downgradient of the source area, or to create reactive barriers to prevent further migration of a plume. Under the right conditions, bioremediation can be used to treat a source area, including those that contain NAPLs.

Development Status and Availability

The following checklist provides a summary of the development and implementation status of air sparging:

☐ At the laboratory/bench scale and shows promise

☐ In pilot studies

☒ At full scale

☒ To remediate an entire site (source and plume)

☐ To remediate a source only

☒ As part of a technology train

☐ As the final remedy at multiple sites

☐ To successfully attain cleanup goals in multiple sites

Enhanced aerobic bioremediation is available through the following vendors:

☒ Commercially available nationwide

☐ Commercially available through limited vendors because of licensing or specialized equipment

☐ Research organizations and academia

Applicability

|

Contaminant Class Applicability Rating for Enhanced Aerobic Bioremediation (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness, ♢ Level of Effectiveness dependent upon specific contaminant and its application/design, I/D Insufficient Data) | ||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| ● | ● | ◐ | ○ | ◐ | ◐ | ○ | ◐ | I/D |

Enhanced in situ aerobic bioremediation is widely used to treat a variety of petroleum hydrocarbon chemicals, including benzene, toluene, ethylbenzene, and xylenes (BTEX); other volatile organic compounds (VOCs) such as formaldehyde, alcohols, and ketones; and a wide-range of semi-volatile organic compounds (SVOCs). These contaminants are readily metabolized by existing native microbial populations, but may need to be stimulated to support biodegradation if subsurface conditions are oxygen deficient (ITRC, 2009b). However, for many classes of compounds, the level of effectiveness is highly dependent on the specific compound(s) being treated. For instance, benzo(a)pyrene and other higher molecular weight polycyclic aromatic hydrocarbons (PAHs) comprised of four benzene rings or more are highly recalcitrant, while naphthalene and methyl naphthalene and other PAHs having three benzene rings or less are readily biodegradable. A mix of these readily biodegradable and recalcitrant PAHs can be found at petroleum hydrocarbon sites depending on the fuel source. Similarly, vinyl chloride, a halogenated VOC, degrades rapidly under aerobic conditions; however, dichloroethene is less amenable to aerobic biodegradation, and direct metabolism of trichloroethene only occurs under anaerobic or cometabolic conditions. Pentachlorophenol (PCP) is a halogenated SVOC that can be degraded both aerobically and anaerobically if the necessary microbial degrader populations are present.

Biodegradation of the nitro groups found in energetic compounds such as trinitrotoluene (TNT), Royal Demolition Explosive (or HMX) are generally not biodegradable via direct aerobic processes, but can occur through cometabolic pathways when an appropriate substrate is present (EXWC, 2015) or through anaerobic pathways. Similarly, biodegradation of the emerging contaminant, 1,4-dioxane, also is known to occur via a cometabolic pathway. Additional information on cometabolic and other anaerobic processes for non-chlorinated VOCs can be found here.

While enhanced in situ aerobic bioremediation (or any other remediation technology) cannot degrade (i.e., reduce mass of) inorganic contaminants, the introduction of an oxygen source can change the oxidation state of inorganics. By changing the oxidation state, the inorganics could adsorb or become immobilized onto soil particulates, precipitate in solution, and accumulate in microorganism cells. For instance, dissolved arsenic is one metal that can be immobilized in situ by introducing oxygen to change its valence state.

Enhanced in situ aerobic bioremediation is suitable for sites where the aquifer characteristics allow effective delivery and mixing of the amendments (i.e., permeability >10-4 cm/sec), and where regulatory constraints do not inhibit operations (Hazen, 2010). Bioremediation is especially effective for remediating residual contamination following primary source removal (NAVFAC, 2000; ITRC, 2009a).

Cost

Similar to many in situ remediation technologies, the most critical cost factors are associated with the contaminant mass to be treated, the nature and extent of contamination (i.e., size of the treatment area), the ability to adequately distribute and contact the amendments with the contaminant mass to be treated, and the number of injection points/wells required. As with all in situ technologies, application costs vary according to site conditions and contaminants and the treatment life-cycle duration. Adequately characterizing the site and developing a comprehensive conceptual site model is essential to optimizing the treatment effectiveness and overall life cycle costs. The major cost drivers and corresponding factors that can influence enhanced aerobic bioremediation include:

Upfront Costs

- Treatability testing. Bench-scale and/or pilot studies may be required to demonstrate effectiveness at a particular site.

- Equipment requirements. The type and complexity of equipment is dictated by the oxygen delivery method, site hydrogeology, and need for permeability enhancement techniques.

- Labor. Labor to introduce and distribute the amendments is dictated by the design and complexity of the oxygen delivery equipment.

- Oxygen delivery method. Equipment requirements for biosparging are limited to a blower/compressor and ancillary measurement and controls, while ozone sparging also includes a more costly ozone generation system. Equipment requirements for groundwater recirculation may include a groundwater treatment system to remove contaminants prior to re-injection, one or more chemical storage tanks, transfer and chemical metering pumps, and ancillary measurement and controls. Housing for the equipment may be required based on site location to prevent exposure to weather and for security purposes.

- Amendments. Types and quantities of oxygen and other amendments are dictated by the oxygen delivery method, contaminant type, contaminant mass to be treated and nutrient requirements.

- Injection points and wells. The number of injection points/wells required (also extraction wells for groundwater recirculation) are dictated by the size of the treatment area and site hydrogeologic conditions.

Operation and Maintenance Costs

- Oxygen delivery method. Costs are highly dependent on the delivery method used. For instance, placing absorbent socks into existing wells and periodically monitoring changes in oxygen concentration requires very little labor; however, a recirculation system that applies ozone and/or hydrogen peroxide can be labor intensive, based on the complexity of treatment equipment operation and maintenance requirements, and potential fouling that must be addressed. Continuous oxygen delivery systems, including biosparging, ozone sparging, and groundwater recirculation, require periodic operation, maintenance, and monitoring and utilities to operate. Biosparging labor and utility requirements tend to be low, while labor and utility requirements for ozone sparging are higher.

- Reapplication of amendments. Reapplication of amendments over multiple events for ORC injections may be required, since these amendments become depleted over time.

- Monitoring requirements after amendment addition.

- Treatment timeframe.

The list above highlights those cost dependencies specific for enhanced aerobic bioremediation. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be obtained using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

Full-scale implementation typically can take between 1 and 4 years depending on the approach taken and the extent of contamination. Treatment timeframes can be much longer for complex sites having significant source area contaminant mass, large plumes, and/or high initial dissolved phase contaminant concentrations. At many sites, multiple applications of amendments are necessary to sustain the redox conditions and corresponding microbial populations as the effects of the amendments diminish. Primary factors that influence the duration of enhanced in situ aerobic bioremediation include:

- Remedial goals and remedial action objectives.

- Biodegradation rates and bioavailability of the contaminants of concern.

- Presence of NAPL and initial concentrations of contaminants of concern.

- Treatment application (source area treatment, dissolved plume treatment, containment).

- Ability to achieve uniform distribution and sustained concentrations of oxygen or amendments in the aquifer.

Implementability Considerations

The following are key considerations associated with implementing enhanced in situ aerobic bioremediation:

- Bench-scale and/or pilot-scale studies are recommended to determine if the technology is feasible, particularly for design optimization, large sites, or complex geology/hydrogeology in the subsurface.

- Groundwater recirculation can be more cost effective than other delivery methods for treatment of larger plumes, as well as highly transmissive aquifer units.

- High concentrations of contaminants (e.g., TPH greater than 50,000 parts per million [ppm]) may be toxic to microbes and/or not bioavailable. Moderate to high levels of immobilized NAPL mass within the capillary/smear zone and shallow saturated zone may be treated more cost effectively by other in situ technologies (e.g., air sparging, multi-phase extraction, thermal treatment).

- A method of hydraulic control may be needed to prevent contaminants from migrating outside of the active treatment areas.

- Subsurface heterogeneity can impede the delivery of treatment fluid throughout different contaminated zones, resulting in disproportionately slow remediation (or untreated pockets) of less permeable zones where advective groundwater flow is limited. Rebound from matrix diffusion must also be accounted for in decision-making and the need to establish criteria to discontinue active treatment.

- May be difficult to implement in low-permeability aquifers (<10-4 cm/sec) (Hazen, 2010). Higher injection pressures or permeability enhancement techniques (e.g., hydraulic or pneumatic fracturing) may be considered to improve oxygen and amendment distribution for these conditions.

- Both biotic and abiotic oxygen sinks can increase cost and duration of the remedy. Continuous oxygen delivery techniques (ozone and biosparging and groundwater recirculation) may be more cost effective than direct-push delivery of ORCs under highly anaerobic conditions that are either natural or contaminant-induced.

- Injection wells and/or infiltration galleries may become plugged by microbial growth or mineral precipitates, which may require pressure jetting, treatment with a biocide, and/or re-development.

- Hydrogen peroxide and ozone are hazardous chemicals. Appropriate safety precautions should be taken during handling and application.

- Heavy metals are not treated by this method, and can be toxic to microorganisms at high concentrations.

- High concentrations of hydrogen peroxide (>100 to 200 ppm) and ozone 3 approach the solubility limit in water and can inhibit microbial activity (ITRC, 2009a).

- VOC vapor migration may occur as a result of biosparging. Although generally not a concern due to low sparge rates, vapor intrusion may be an issue if nearby buildings or other receptors are present. Mitigation and treatment using soil vapor extraction may be required.

- Although in situ bioremediation has been demonstrated in cold weather climates, low temperatures slow the remediation process.

- Re-injection wells or infiltration galleries may require permits or be prohibited.

- The level of treatment that can be achieved by mixing solid ORCs into an excavation backfill is typically limited to a short duration involving lower residual contaminant mass levels, and to the volume of soil that is well mixed with the amendment (and possibly to shallow horizons in close proximity beneath the mixed soils). This type of delivery technique is not typically effective for remediating residual NAPL or appreciable source mass remaining below the excavation depth.

Resources

EPA. A Citizen's Guide to Bioremediation (2001)

A fact sheet to help answer simple questions regarding bioremediation.

EPA. Enhanced Aerobic Bioremediation (2004)

This chapter (XII) provides a brief description of several of the enhanced aerobic bioremediation technologies. This chapter is taken from a larger report: How to Evaluate Alternative Cleanup Technologies for Underground Storage Tank Sites: A Guide for Corrective Action Plan Reviewers (EPA 510-B-94-003; EPA 510-B-95-007; EPA 510-R-04-002).

EPA. Engineering Issue: In Situ and Ex Situ Biodegradation Technologies for Remediation of Contaminated Sites. EPA-625-R-06-015. (2006)

The purpose of this Engineering Issue paper for biodegradation technologies is to summarize current information on bioremediation and to convey that information clearly and concisely to site managers.

EPA. CLU-IN on Aerobic Bioremediation

EPA website on direct aerobic bioremediation technologies.

Hazen, T.C. In Situ Groundwater Bioremediation (2010). In Chapter 13 in Part 24 of the Handbook of Hydrocarbon and Lipid Microbiology. Springer-Verlag Berlin Heidelberg, ISBN: 978-3-540-77587-4, p 2584-2596.

This book chapter provides an overview of bioremediation concepts involving intrinsic biodegradation, biostimulation, and bioaugmentation for a variety of contaminants, including chlorinated hydrocarbons.

ITRC. A Systematic Approach to In Situ Bioremediation in Groundwater, Including Decision Trees on In Situ Bioremediation for Nitrates, Carbon Tetrachloride, and Perchlorate (2002)

Provides guidance for the systematic characterization, evaluation, and appropriate design and testing of in situ bioremediation for any biotreatable contaminant.

ITRC. Technical and Regulatory Guidance for In Situ Chemical Oxidation of Contaminated Soil and Groundwater Second Edition (2005).

This document describes the design and application of in situ chemical oxidation reagents including hydrogen peroxide and ozone.

ITRC. Evaluating LNAPL Remedial Technologies (2009a)

This guidance provides a framework to help stakeholders select the best-suited light non-aqueous phase liquid (LNAPL) remedial technology for an LNAPL site and will help the regulator and others understand what technologies apply in different site situations.

ITRC. Evaluating Natural Source Zone Depletion at Sites with LNAPL (2009b)

This document provides a technical overview of natural source zone depletion (NSZD) for LNAPLs, which, when appropriately evaluated, can serve as an objective benchmark by which to compare the relative effectiveness of different remedial alternatives.

NAVFAC. In Situ Bioremediation of MTBE in Groundwater Using a Bacterial Culture NCB-45-00 (2001a)

Study report on bacterial culture BC-4 injected into a 100 ft x 100 ft in situ bioreactor to treat an MTBE plume.

NAVFAC. Air Sparging Guidance Document (2001b)

This document provides detailed information covering all aspects of air sparging including feasibility analysis, regulatory and permitting issues, pilot testing, system design and construction, operation and maintenance, and site closure.

NAVFAC. Natural Pressure-Driven Passive Bioventing (2003)

Final report for a project involving short-term testing at 10 eastern U.S. sites, additional site characterization and testing at two of the sites (Fort Stewart, GA and Robins AFB, GA) to evaluate the potential to use "passive bioventing" in the eastern U.S.

Some examples include ORC®, ORC Advanced®, and Permeox® Ultra. Others may be available. The FRTR does not endorse a particular compound. Selection should be based on site-specific conditions, available data from historical applications, and vendor information. ↩

Some examples include ORC®, ORC Advanced®, and Permeox® Ultra. Others may be available. The FRTR does not endorse a particular compound. Selection should be based on site-specific conditions, available data from historical applications, and vendor information. ↩

Groundwater recirculation also can be used with air or other oxygen sources. ↩

Groundwater recirculation also can be used with air or other oxygen sources. ↩

Very high concentrations of ozone over a long injection timeframe is required to achieve complete biological inactivation (ITRC, 2005). ↩

Very high concentrations of ozone over a long injection timeframe is required to achieve complete biological inactivation (ITRC, 2005). ↩