Soil Vapor Extraction

On this page:

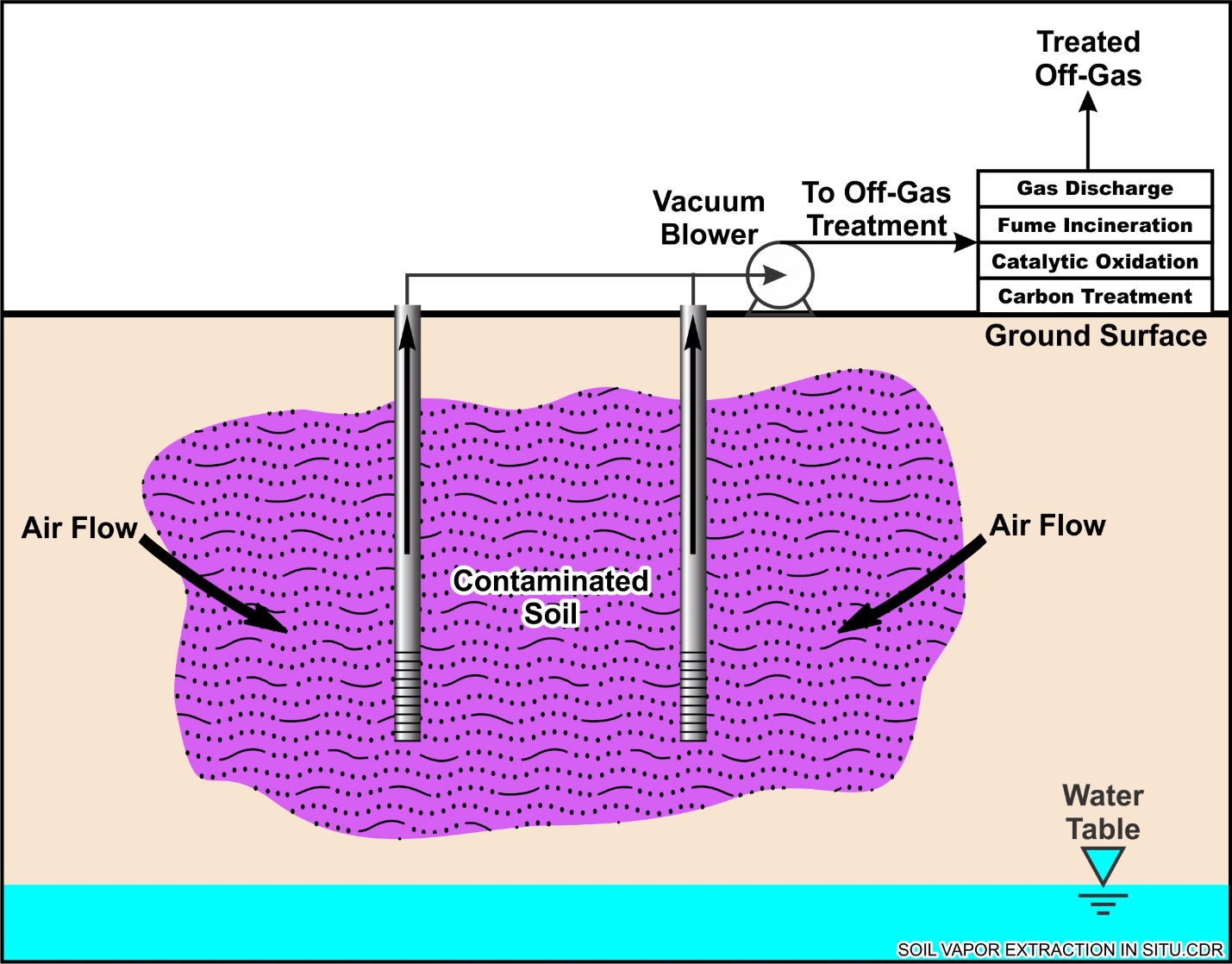

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

Schematic

This information may be reproduced without restriction as long as the source attribution is included.

Soil Vapor Extraction

Introduction

Soil vapor extraction (SVE) involves the application of a vacuum in the vadose zone to induce the controlled flow of air and removal of volatile and some semivolatile contaminants from the subsurface. SVE is applicable to the treatment of contamination located above the water table in unsaturated (vadose) zone soil. SVE system configurations can include vertical and/or horizontal extraction wells as warranted by site-specific conditions. The extracted soil gas is typically treated aboveground to recover or destroy the contaminants. The vapor treatment technology will depend upon the contaminant types, their extracted soil gas concentrations, and local and state air discharge regulations. SVE is often coupled with other in situ treatment technologies such as soil fracturing, air sparging, pump-and-treat, and/or thermal treatment technologies to enhance mass removal and control contaminant migration in the vadose zone.

Other Technology Names

In Situ Soil Venting

Soil Vacuum Extraction

Vacuum Extraction

Description

SVE establishes a vacuum in the subsurface to create a pressure/concentration gradient that allows for the mass transfer of applicable contaminants from the NAPL or adsorbed phases and transfer of constituents dissolved in soil moisture to the vapor phase. The vapor is then recovered from the subsurface through extraction wells and is then treated aboveground to recover or destroy the contaminants. The components of an SVE system can include extraction wells, conveyance piping, manifold, air filter, vacuum blower, silencer, air/water separator, valves, instrumentation/controls, an off-gas treatment system, influent and effluent vapor sampling ports, and vacuum/vapor monitoring probes or wells.

The mass transfer process is influenced by several properties of the contaminant and subsurface conditions, as well as the magnitude of the applied vacuum. Contaminant properties that influence removal by SVE include the Henry's Law constant, vapor pressure, boiling point, and soil adsorption coefficient. The subsurface conditions that influence SVE effectiveness include soil lithology and heterogeneity, temperature, soil moisture and natural organic carbon content, and depth to groundwater. Lower permeability zones typically have higher water saturation and lower gas-filled porosity, which tends to inhibit air flow. Therefore, contaminant mass removal occurs primarily from the higher permeability zones; while challenges are experienced with contaminant mass removal from lower permeability zones, areas with higher moisture, or higher contaminant adsorption to the soil matrix (PNNL, 2013). At some sites, fracturing of low permeability zones has been conducted to increase the permeability and contaminant removal by SVE.

It is important to be aware of the above factors when designing SVE systems and deciding upon extraction well design and placement. At sites with complex geologic characteristics, for example, having stratification and variable soil permeability, pilot-scale studies are particularly useful to obtain site-specific data for design. Pilot studies should be performed to provide design information, including the relationship between extraction well airflow rates, vacuum required to achieve capture at targeted locations and depths, and contaminant mass removal rates, to optimize the system design. The pilot study data should include sufficient vacuum data with distance and depth from the extraction well to allow for the evaluation of airflow pathways and anisotropy (vertical versus horizontal gradient) and extrapolate airflow distribution/pore volume exchanges. The zone of adequate air throughput for vertical SVE wells is typically a few tens of feet for sandy/silty soil types and tens to over 100 ft for sand to gravel soil types (NAVFAC, 2001).

Adequate air throughput/pore volume exchanges are the appropriate criteria for designing extraction well airflow rates and spacings. Since observed vacuum itself does not necessarily equate to a specific airflow/pore volume exchange rate needed to achieve the necessary level of contaminant mass removal, it is a poor basis for assessing extraction well spacing (USACE, 2002; EPA, 2001). Depending on the starting soil concentration, site conditions, and desired endpoint, hundreds to a few thousand (or more) pore-volume exchanges may be required through each given horizontal and vertical cross-section of the treatment area to uniformly achieve soil cleanup goals (USACE, 2002). Because of the prevalence of surface air recharge and vertical anisotropy at a large percentage of remediation sites, a common design error that leads to less effective SVE treatment is to space extraction wells too far apart based on vacuum influence measured during the pilot study. Vertical surface air recharge results in a larger percentage of the total extraction well airflow rate originating at a distance much closer to the extraction well than what would be extrapolated from measured vacuum influence, which means that fewer air pore volume exchanges occur with increasing distance through cross-sections.

Vertical extraction wells are typically used at depths of 1.5 meters (5 feet) or greater and have been successfully applied as deep as 91 meters (300 feet). Horizontal extraction wells (installed in trenches or horizontal borings via directional drilling) can be used as warranted by contaminant zone geometry, drill rig access, presence of structures overlying contaminant plumes, or other site-specific factors. A geomembrane cover (or surface pavement, but be aware of permeable fill materials under the pavement) may be placed over the soil surface to prevent short circuiting of recharge air from the surface, which will serve to increase the horizontal airflow rate with distance through the treatment zone. In addition, aquifer pumping may be used at some sites to reduce groundwater upwelling induced by the vacuum, or to draw down the water table and expose and contact more of the contaminant mass that can be immobilized within the capillary/smear zone with the airflow to increase effectiveness of treatment.

Various types of blowers/pumps can be used to apply vacuum/airflow required for SVE treatment. Common types include the following: 1) positive displacement (e.g., rotary lobe) blowers that operate at higher vacuums at lower, but more consistent, airflow rates used for moderate to lower permeability applications; 2) centrifugal/regenerative blowers that operate at lower vacuums and higher airflow rates used for higher permeability applications; and 3) liquid ring pumps that operate at the highest available vacuums, and can handle both vapors and liquids, used for lower permeability sites or multi-phase extraction (MPE) applications.

Off-gas treatment from SVE operations is typically accomplished with the use of vapor phase granular activated carbon (GAC), thermal oxidation, or catalytic oxidation. The specific off-gas treatment technology used will depend upon the contaminant types, their concentrations, and local and state air discharge regulations. SVE systems also typically include an air/water separator and particulate filter to remove moisture and particulates prior to performing other types of treatment.

Various enhancements are possible to improve SVE performance, including hydraulic or pneumatic fracturing of the subsurface or combining SVE with air sparging or in situ thermal treatment technologies. Under certain conditions, thermal enhancements to SVE may be considered to improve volatility through hot air, steam injection, or other heating methods (see extreme SVE for 1,4-dioxane removal as demonstrated through ESTCP ER-201326).

Wastewater collected in the air/water separator is typically contaminated. The collected water is usually the result of soil moisture that becomes entrained in the airflow, but can also be generated from liquid condensation in piping if the ambient air temperature is less than the aquifer temperature. This water is either periodically removed and disposed offsite at a licensed facility or treated onsite, usually with liquid phase GAC and discharged to a sanitary or storm sewer. If wastewater requires on-site treatment, treated effluent must comply with applicable discharge permits.

Development Status and Availability

The following checklist provides a summary of the development and implementation status of SVE remediation:

☐ At the laboratory/bench scale and shows promise

☒ In pilot studies

☒ At full scale

☒ To remediate an entire site (source in vadose zone)

☐ To remediate a source only

☒ As part of a technology train

☒ As the final remedy at multiple sites

☒ To successfully attain cleanup goals in multiple sites

SVE remediation is available through the following vendors:

☒ Commercially available nationwide

☐ Commercially available through limited vendors because of licensing or specialized equipment

☐ Research organizations and academia

Applicability

|

Contaminant Class Applicability Rating for SVE Remediation (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness, I/D Insufficient Data, N/A Not Applicable) |

||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| 1 | 2 | 3 | ||||||

| ● | ● | ◐ | ◐ | ◐ | N/A | N/A | N/A | ◐ |

SVE can be used to facilitate treatment of lower water solubility VOCs in soils and is the preferred presumptive remedy for this purpose under the Environmental Protection Agency's (EPA's) Comprehensive Environmental Response, Compensation and Liability Act (CERCLA) process (EPA, 1996). It is known to be effective for the removal of a range of chlorinated solvents and the lighter fraction of petroleum hydrocarbons with higher Henry's Law constants. SVE alone is not very effective at treating SVOCs or certain emerging contaminants, such as 1,4-dioxane and per- and polyfluoroalkyl substances (PFAS), but can be enhanced using in situ thermal treatment technologies. The conventional form of the technology is typically applicable only to VOCs with a dimensionless Henry's Law constant greater than 0.01 or a vapor pressure greater than 0.5 mm Hg (0.02 inches Hg). SVE will not remove heavy oils, metals, polychlorinated biphenyls (PCBs), or dioxins. Because the process involves the continuous flow of air through the soil, it can promote the in situ biodegradation of low-volatility organic compounds amenable to aerobic biodegradation that may be present (e.g., heavier end petroleum hydrocarbons) in the vadose zone.

Soil characteristics, such as moisture content, organic carbon content, and air permeability, also affect SVE effectiveness. This technology is primarily applicable to sites with moderate to higher permeability soils and lower moisture content. The presence of free product prolongs SVE system operation and increases costs of off-gas treatment. High amounts of soil moisture (including surface infiltration) can interfere with successful operation of the technology and increase operating costs. Consequently, SVE may not be effective at removing immobilized residual contaminant mass that accumulates near or just below the depth of the water table (often referred to as the capillary smear zone) without also performing some level of dewatering. Other technologies, such as air sparging or MPE, can be used in combination with SVE to address residual contaminant mass that accumulates near the depth of the water table.

Cost

The most critical cost factors are associated with the contaminant mass and type, soil characteristics, and the extent of contamination (i.e., size and depth of the treatment zone). These factors affect the number of extraction wells needed, the blower capacity and vacuum level required, the need for off-gas treatment, and the length of time required to remediate the site. Major cost drivers include:

Upfront (Capital) Costs

- Volume of contaminated soil requiring treatment, which impacts the type and number of extraction wells required based on the zone of effective treatment for each well, and the required air throughput which impacts the size of the blower and associated treatment equipment.

- Depth of contamination in the vadose zone, which impacts extraction well design and installation costs.

- Need to install transfer piping below grade due to site activities, winter climates, etc. represents a higher cost than aboveground piping.

- Required vacuum and air flow rate, which determine the size of off-gas treatment equipment and system compound, and design/construction of associated structural, mechanical, and electrical components.

- Need for off-gas treatment and regulatory permits.

- Vapor monitoring points (VMPs).

- Presence of aboveground and belowground structures and utilities, which impact well placement.

- Power availability.

- Need for air treatment, including more sophisticated controls (e.g., programmable logic controller and remote telemetry).

- Need to install treatment equipment within an enclosure due to winter climates, security needs, etc. represents a higher cost.

Operation and Maintenance Costs

- Utility costs for required off-gas treatment until contaminant concentrations decrease to a level where treatment can be discontinued.

- Presence of air treatment represents higher cost due to required utilities and greater preventive maintenance requirements and operator attention.

- Amount of water extracted during the process, which usually requires treatment and disposal.

- Treatment duration.

- Routine system operation and maintenance, including labor and materials.

- Power requirements and utility rates based on motor horsepower, which is an artifact of the design airflow rate.

- Soil vapor monitoring and vacuum off-gas treatment sampling and analysis.

The list above highlights those cost dependencies specific to SVE remediation and does not consider the dependencies that are general to most in situ remediation technologies. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be obtained using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

The duration of operation and maintenance for SVE is typically medium-term (e.g., from 1 to 3 years) to long-term (e.g., as long as a building remains occupied for vapor intrusion mitigation purposes). The treatment duration depends on several factors such as contaminant type, extracted soil gas concentrations, and soil characteristics (e.g., heterogeneous very moist soil slows treatment). The SVE system design, including the spacing of extraction wells in relation to the contaminated zone (e.g., area and depth), can also impact duration.

SVE systems may exhibit a diminished rate of contaminant extraction over time, often achieving asymptotic conditions where mass removal rates level off either temporarily or permanently. When this condition occurs, it requires further evaluation of the SVE system and management decisions related to optimization of system design, operational changes, system shutdown, and/or transition to another technology (PNNL, 2013).

Implementability Considerations

The following are key considerations associated with applying SVE remediation:

- Contaminants with low Henry's Law constants are difficult to treat via SVE. Under certain conditions, thermal enhancements to SVE may be considered to improve volatility through hot air, steam injection, or other subsurface heating technologies.

- SVE is not effective in the saturated zone, and extraction well screens must be positioned to account for seasonal variations in water table elevation. At some sites, lowering the water table via pumping (or MPE) may be considered to expose more media to treatment via SVE.

- Geologic framework and degree of lateral and vertical heterogeneity must be considered when designing the system to ensure vapor is effectively removed from all portions of the target interval. For instance, it is easier to induce flow through a sandy interval compared to a silt or clay lens. Also, a clay layer could impede vapor extraction in portions of the contaminated interval if a well is not screened in a manner to account for it.

- Soil with a high percentage of fines and a high degree of water saturation will require higher vacuums, increasing costs, and/or hindering the treatment effectiveness and uniformity.

- Soil with highly variable permeabilities or stratification may result in uneven extraction of gas flow from contaminated zones. After an SVE system is shut down (temporarily or permanently), this can also result in contaminant rebound from lower permeability zones where mass transfer processes were less effective over time. Extraction well design/placement and/or SVE operations (e.g., cycling of extraction wells, pulsed operation), as well as the possible need for fracturing, may need to be taken into account to address varying permeabilities/stratification and the potential for rebound.

- SVE system design should allow for measurement of airflow and contaminant concentrations for the individual extraction wells (versus composite measurements at the blower). The exclusion of individual well measurements will not allow for proper performance evaluation or optimization. For heterogeneous lithology, it is not uncommon for one or a few of the extraction wells screened in a more permeable location to account for almost all of the total airflow. As contaminant removal rates decrease over time, the option to pulse or shut down individual extraction wells with lower contaminant removal rates becomes advantageous.

- The installation of VMPs is recommended for a representative number of locations throughout the treatment zone, as well as distances from the extraction wells, and depths within different soil units for deeper treatment zones. Vacuum measurements at a sufficient number of gas probes allows for an overview extrapolation of airflow rates and distribution patterns throughout the treatment area. Respiration (e.g., oxygen) and contaminant concentration measurements can also be collected to evaluate recharge influence and removal progress, as well as identify potential "dead zones" of ineffective treatment that may require further optimization to address.

- Water infiltration from rainfall and/or water table upwelling into the SVE system can pose several operational problems. Transfer piping needs to be sloped back to the extraction wells or strategically located collection points to prevent line blockage. Suction lifting of larger volumes of shallow groundwater or entrainment of precipitation infiltration into the system can overwhelm the air/water separator and cause severe corrosion and seizing of the blower internal parts (which will require replacement). During periods of heavy rainfall or shallow groundwater, the SVE system may either need to be shut down or the vacuum/airflow reduced to prevent these problems.

- Off-gas treatment is often required and will significantly increase the cost of SVE operations. For example, residual liquids may require treatment/disposal, spent GAC will need to be regenerated or disposed, and thermal/catalytic oxidation may require significant electrical/gas costs to operate. Long-term project planning should allow for sufficient flexibility to change out or discontinue air treatment as the contaminant influent concentrations decrease over time (e.g., use of rental equipment, frequent monitoring of influent versus permit requirements for treatment).

- SVE effectiveness tends to decrease over time eventually reaching asymptotic/plateau conditions. Asymptotic/plateau conditions can be an artifact of contaminant mass removal primarily from the higher permeability zones, while challenges are experienced with contaminant mass removal from lower permeability zones, areas with higher moisture, or higher contaminant adsorption to the soil matrix. Further evaluation of SVE system design and operations are recommended should this occur at a given site. Analysis of the impact that persistent contaminant concentrations may have on groundwater concentrations or vapor intrusion should be done using appropriate modeling tools (e.g., SVEET, PNNL, 2013). Rebound testing and vapor concentration measurements at VMPs should be performed to evaluate residual contaminant levels throughout the treatment area in order to make sound decisions regarding the need for further system optimization or system shutdown.

Resources

EPA. User's Guide to the VOCs in Soils Presumptive Remedy (1996) (PDF) (3 pp, 260 KB)

This User's Guide recommends SVE as a presumptive remedy for sites where VOCs are present in soil and treatment is warranted.

EPA. A Citizen's Guide to Soil Vapor Extraction and Air Sparging (2012) (PDF) (2 pp, 1.63 MB)

This fact sheet is intended for public guidance on the method of SVE to clean up pollution at Superfund and other sites.

Development of Recommendations and Methods to Support Assessment of Soil Venting Performance and Closure EPA/600/R-01/070 (2001) (PDF) (435 pp, 4.03 MB)

The purpose of this document is to improve the current "state of the art" and "state of the science" of soil venting application.

EPA. Soil Vapor Extraction (1995)

This Web site provides an overview and links to guidance for the application of SVE.

ESTCP. EnviroWiki Soil Vapor Extraction

This Web site provides a high-level summary of SVE design, effectiveness, and optimization considerations.

ESTCP. 1,4-Dioxane Removal by Extreme Soil Vapor Extraction

This ESTCP Web site includes links to a final project report and cost and performance report that describes the application of extreme soil vapor extraction (XSVE), an enhancement of SVE, to treat 1,4-dioxane-contaminated soil by incorporating enhancements such as decreased infiltration, increased air flow, focused vapor extraction, and injection of heated air.

PNNL. SVE System Operation, Transition, and Closure Guidance (2013) (PDF) (130 pp, 2.02 MB)

This document provides guidance pertaining to the operation and optimization of SVE systems and the performance data to be evaluated to determine whether the system should be optimized, terminated, or transitioned to another technology to replace or augment SVE.

PNNL. Soil Vapor Extraction System Guidance

This Web site contains links to software, flow charts, and guidance for assessing SVE system performance.

USACE. Engineering Manual: Soil Vapor Extraction and Bioventing (2002) (PDF) (424 pp, 3.59 MB)

This manual provides practical guidance for the design and operation of SVE and bioventing systems.

USAF. Guidance on Soil Vapor Extraction Optimization (2001) (PDF) (90 pp, 2.79 MB)

This document provides practical guidance on the optimization of SVE systems to achieve remediation goals in a cost-effective manner.

N/A for inorganics and radionuclides: examples of exceptions are mercury and radon, which are volatile and could be removed by SVE. However, these would not be typical technology applications. ↩

N/A for inorganics and radionuclides: examples of exceptions are mercury and radon, which are volatile and could be removed by SVE. However, these would not be typical technology applications. ↩

N/A for inorganics and radionuclides: examples of exceptions are mercury and radon, which are volatile and could be removed by SVE. However, these would not be typical technology applications. ↩

N/A for inorganics and radionuclides: examples of exceptions are mercury and radon, which are volatile and could be removed by SVE. However, these would not be typical technology applications. ↩

Based on recent research of extreme SVE at elevated temperatures for 1,4-dioxane removal (ESTCP ER-201326). ↩

Based on recent research of extreme SVE at elevated temperatures for 1,4-dioxane removal (ESTCP ER-201326) ↩