Soil Flushing

On this page:

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

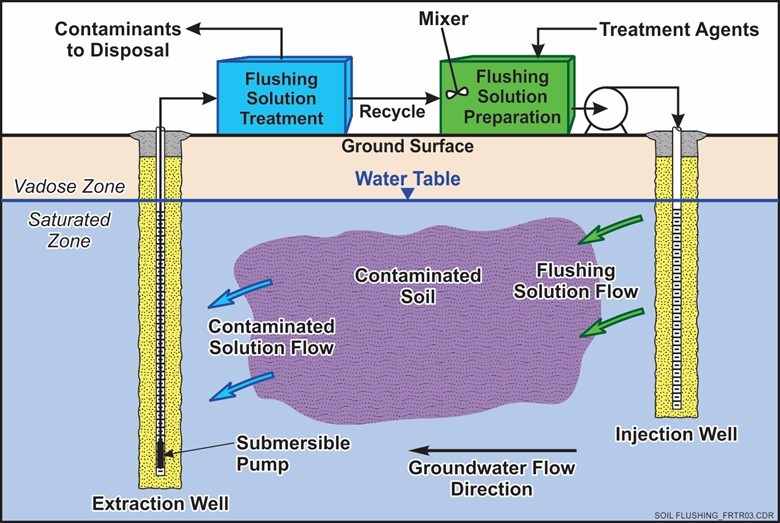

Schematic

This information may be reproduced without restriction as long as the source attribution is included

Soil Flushing

Introduction

Soil flushing is an in situ process that extracts contaminants from the formation using water, possibly combined with other suitable amendments such as a surfactant, cosolvent, acid, or base. The aqueous solution is applied to the soil surface or introduced into the vadose zone, saturated zone or both. Contaminants in the soil partition into the flushing solution by mechanisms such as solubilization, emulsification, or chemical reaction. The contaminant-laden solution is then recovered aboveground through a series of extraction wells, points or trenches and subsequently treated.

Other Technology Names

Cosolvent Flushing

Cosolvent Enhancements

In Situ Flushing

Surfactant Enhanced Aquifer Remediation

Surfactant Flooding

Water Flooding

Description

Soil flushing systems are designed to treat contaminants of concern (COCs) in a source area. They generally are not designed to treat dissolved-phase plumes. Soil flushing is similar to soil washing, with the primary difference being that soil flushing is performed in situ while soil washing is performed (ex situ) on excavated soil. At sites having shallow groundwater and/or when it is desirable to only treat the vadose zone, the washing fluids can be introduced at ground surface and allowed to infiltrate downward into the contaminated portion of the soil. However, at deeper sites and when it is desirable to treat the saturated zone, it is common to design a system using injection wells and points and/or infiltration trenches to introduce the fluids. Injection is usually performed upgradient of the contaminant source and extraction wells, points, or trenches are installed downgradient of the source to recover the contaminant-laden wash solution and to create a capture zone to reduce the likelihood of uncontrolled transport of COCs out of the treatment zone. Groundwater flow capture modeling should be considered to help design an appropriate network of recovery wells. Sentinel wells may be installed immediately outside the treatment area to monitor changes in concentrations at those locations since flushing mobilizes contaminants, which can migrate through preferential pathways.

The type of washing fluid is selected based on the chemical and physical properties of COCs at the site, site-specific lithology, and project objectives. At some sites, water may be the only fluid needed; however, oftentimes surfactants, acids or bases, alcohols and other reagents are required as additives. Acids and bases are useful for solubilizing a variety of metals, while surfactants help to reduce surface tension and mobilize organic contaminants. Chelating and reducing agents also may be incorporated into the wash solution to remove various COCs. When a reagent such as a miscible organic solvent (e.g., methanol, ethanol, or propanol) is introduced with water or with water and a surfactant, the process is referred to as cosolvent flushing. Nutrients also may be added and distributed with the flushing solution to promote contaminant bioremediation.

Flushing solutions are frequently formulated with surfactants to facilitate removal of organic COCs from soil. Surfactants have both hydrophilic and hydrophobic portions of their molecular structure that cause them to aggregate at the interface of fluids with different polarities, like a non-polar contaminant and water. One of the main characteristics of surfactants is that they decrease the interfacial surface tension, which facilitates desorption of the COCs from the soil allowing them to be recovered in the aqueous phase. Naturally occurring biosurfactants may be used, which are not likely to adversely impact the aquifer and are easily biodegradable. One example of a biosurfactant is d-limonene, a turpine that can be derived from naturally occurring materials such as orange peels or pinecones.

The addition of the flushing fluids may be performed in the vadose zone to target contaminated soil and/or may be applied to the saturated zone. When applied to the saturated zone and used to treat non-aqueous phase liquids (NAPLs), the application may be referred to as surfactant enhanced aquifer remediation (SEAR).

To promote sustainable remediation, recovered flushing fluids should be recycled and reused to the maximum extent practical. The separation of the surfactants from the recovered flushing fluids and removal of COCs is performed aboveground using one or more water treatment processes, based on the types and concentrations of flushing fluids used, and types and concentrations of COCs present. Additional treatment may be required to remove fine materials from the water and to remove COCs from recovered fluids not reused in the process prior to disposing them to local, publicly owned wastewater treatment works or receiving surface water bodies. Treatment may include sand filters, coagulation and flocculation and/or dissolved air flotation performed to remove fines and some COCs. Hydrophobic clay may be used to remove light non-aqueous phase liquids (LNAPLS). Further water treatment may be performed using granular activated carbon or air stripping to remove VOCs and SVOCs and chelating agents to remove metals. However, the specific type and sequence of treatment required is based on disposal requirements and types and concentrations of COCs present in the water stream.

The separation of surfactants, solvents, and COCs from recovered flushing fluids for reuse in the process is a major factor in the cost of soil flushing. Treatment of the recovered fluids results in process sludges and residual solids, such as spent carbon and spent ion exchange resin, which must be appropriately treated before disposal. Bench-scale laboratory testing may be performed using site soil and groundwater to test the efficacy of potential flushing reagents and concentrations to remove specific COCs and evaluate a suitable approach for separating and treating the recovered fluids.

Soil flushing may be combined with other technologies to enhance their performance. For instance, flushing can be used with multi-phase extraction or other pump and treat technologies to reduce the surface tension of LNAPLS to enhance removal by the recovery system. Similarly, surfactant addition may facilitate removal of dense non-aqueous phase liquids (DNAPLs), as well as provide a carbon source in the aquifer that could facilitate anaerobic bioremediation for subsequent remedies applied after soil flushing such as reductive dechlorination or monitored natural attenuation.

Development Status and Availability

The following checklist provides a summary of the development and implementation status of soil flushing:

☐ At the laboratory/bench scale and shows promise

☐ In pilot studies

☒ At full scale

☐ To remediate an entire site (source and plume)

☒ To remediate a source only

☒ As part of a technology train

☒ As the final remedy at multiple sites

☐ To successfully attain cleanup goals in multiple sites

Soil washing is available through the following vendors:

☒ Commercially available nationwide

☐ Commercially available through limited vendors because of licensing or specialized equipment

☐ Research organizations and academia

Applicability

|

Contaminant Class Applicability Rating for Soil Flushing (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness, ♢ Level of Effectiveness dependent upon specific contaminant and its application/design, I/D Insufficient Data) | ||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| ● | ● | ● | ● | ● | ● | ● | ● | I/D |

Soil flushing has been demonstrated to effectively treat soils containing a wide range of contaminants including volatile organic compounds (VOCs), semi-volatile organic compounds (SVOCs), fuels, inorganics, radionuclides, and munitions constituents. Effectiveness is dependent on the specific COCs within a class of contaminants because it is more difficult to remove contaminants that have a greater affinity (sorption capacity) for soil and lower aqueous solubility. Hence, soil flushing can be effective for emerging contaminants that have low sorption capacities and high solubilities, such as perchlorate or per- and polyfluorinated alkyl substances (PFAS), although limited data are available for the latter. Soil flushing also can be used to facilitate removal of NAPLs either alone or in conjunction with other technologies, such as multiphase extraction or in situ heating.

The physical properties of the soil also strongly impact the effectiveness of soil flushing. As with many in situ technologies, its effectiveness requires adequate distribution of the amendments through the vadose and/or saturated zone and achieving contact with the contaminated soils. Lithologies comprised of fine-grained material, interbedded lenses of more permeable and less permeable materials, and fractured bedrock sites can be expected to be more difficult to treat than those containing sandy, relatively homogeneous soils.

Cost

Soil flushing is an aggressive in situ technology. The cost to implement it is dependent on a number of factors including the size (area and volume) of the contaminated soil, depth of the contamination, soil type, contaminant type, disposal requirements, required equipment, and desired concentration endpoints of the COCs in soil. Major cost drivers include:

Upfront Costs

- Areal extent of contamination. Larger sites generally require a greater number of injection and extraction wells, points, and/or trenches compared to smaller sites.

- Depth of contamination. Deeper contamination is more costly to treat due to increased costs to install injection and extraction wells, points, and/or trenches. Larger vertical treatment intervals also increase cost because the treatment volume for a given treatment footprint will be greater and it becomes more difficult to ensure that the flushing solution is adequately distributed across the larger treatment interval.

- Soil lithology. It is more challenging to introduce and distribute amendments into less permeable soils, requiring more closely spaced injection and extraction wells, points and/or trenches compared to more permeable sites. Also, sites with heterogenous lithology may require specialized techniques (e.g., nested wells) to facilitate introduction of amendments into discrete treatment intervals.

- Types and concentrations of COCs and flushing reagents. The COCs and their concentrations influence the types of flushing reagents required, both of which will impact the type of aboveground water treatment processes needed to separate the COCs from the flushing solution and flushing solution from groundwater prior to reuse.

Operation and Maintenance Costs

- Treatment duration, which is influenced by starting concentrations and regulatory endpoints.

- Types, volumes, and concentrations of reagents required to perform separation, which are influenced by the physical properties of the soil and the physical/chemical properties and mixture of COCs in the soil.

- The separation, treatment and reuse of flushing fluids.

- Frequency of injection events.

- The complexity and associated operation, maintenance and monitoring requirements required to separate the COCs from the flushing fluids to permit reuse of the flushing fluid.

- Treatment and disposal of water treatment media including spent carbon and hydrophobic clay sludges.

The list above highlights those cost dependencies specific to soil flushing and does not consider the dependencies that are general to most in situ remediation technologies. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be obtained using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

Soil flushing is a medium-term treatment technology expected to require weeks to one year or more to treat the contaminated media. Duration is affected by the size of the site; the number and spacing of injection points, wells, and trenches that are used; in situ soil characteristics including permeability and anisotropy; and cleanup goals. In addition, treatment rates vary depending on the physical properties of the soil and types of contaminants present. COCs that are strongly bound to soil will take longer to remove than those that are bound by weak forces. Similarly, COCs may be difficult to remove from low permeability zones requiring additional treatment time.

Implementability Considerations

The following are key considerations associated with applying soil washing:

- Soils containing a large fraction of clay and silts may not be treated effectively due to the inability to achieve adequate contact between the flushing solution and contaminated soil.

- High resolution site characterization of the source area contaminant distribution and stratigraphy can improve implementation, particularly for sites with NAPL.

- The flushing solution should be recovered, treated, and recycled. Treatment can be costly and time consuming.

- The effectiveness of flushing with water alone can be limited by the solubility of the COCs.

- It is not possible to recover all of the flushing solution and residual washing solution may remain adhered to soil particles and/or dissolved in groundwater, which can solubilize and facilitate migration of COCs.

- Complex waste mixtures (e.g., multiple contaminant classes) increase the difficulty of formulating a single flushing solution.

- The flushing solution must be compatible with the in situ environment.

- Subsurface heterogeneity can interfere with uniform distribution (and recovery) of flushing solutions.

- Surfactants can adhere to soil and reduce effective soil porosity.

- The flushing solution injection and collection systems must be designed and operated to limit the spread of contaminants to clean areas.

- Bench-scale laboratory testing should be performed to identify a flushing solution and concentration to optimize removal of site-specific COCs.

- As with other in situ technologies that rely on the introduction of amendments, it is important to achieve good hydraulic control to prevent spreading contaminants beyond the treatment zone. Installation of temporary sentinel wells outside of the treatment area should be considered to monitor changes in groundwater and/or provide a means to recover groundwater should data indicate that contaminants or the flushing solution are not being adequately captured within the treatment zone.

- Regulatory requirements pertaining to the introduction of fluids into the aquifer must be considered.

Resources

EPA In Situ Flushing Web Page

This web page provides an overview of the technology, as well as information on guidance documents, case studies for application, training and additional resources.

EPA. A Citizens Guide to In Situ Soil Flushing (1996) (PDF) (4 pp, 25.3 KB)

A fact sheet intended for public guidance on soil flushing to clean up pollution at Superfund and other sites.

EPA. In Situ Flushing with Surfactants and Cosolvents (2000) (PDF) (36 pp, 122 KB)

This paper outlines the major principles associated with the use of surfactants and cosolvents, and briefly summarizes surfactant and cosolvent studies, demonstrations, and full-scale implementation.

EPA. In Situ Treatment Technologies for Contaminated Soil (2006) (PDF) (35 pp, 939 KB)

This Engineering Forum Issue Paper provides a summary of a number of in situ technologies, including soil flushing, to treat contaminated soil.

Indiana Department of Transportation (INDOT) Guidance Document for In-Situ Soil Flushing (2007) (PDF) (48 pp, 847 KB)

This document is intended to provide soil flushing guidance for decision makers and users involved in evaluating remediation strategies. It describes key factors that should be considered during the selection, design and implementation of soil flushing.

ITRC. Technical and Regulatory Guidance for Surfactant/Cosolvent Flushing of DNAPL Source Zones. DNAPL-3 (2003) (PDF) (140 pp, 1.02 MB)

This document is intended to serve as a technical and regulatory guide for stakeholders, regulators, technology decision makers, and others involved in selecting and implementing surfactant/cosolvent flushing of DNAPLs as a remedial action.

Groundwater Remediation Technologies Analysis Center. In Situ Flushing (1997) (PDF) (24 pp, 181 KB)

This report provides an overview of the general principals and techniques, applicability, and limitations of soil flushing.

NAVFAC. Surfactant-Enhanced Aquifer Remediation (SEAR) Design Manual (2002) (PDF) (110 pp, 4.17 MB)

This technical report provides guidance to evaluate and apply in situ surfactant flooding or SEAR at sites contaminated with DNAPL.