Soil Washing

On this page:

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

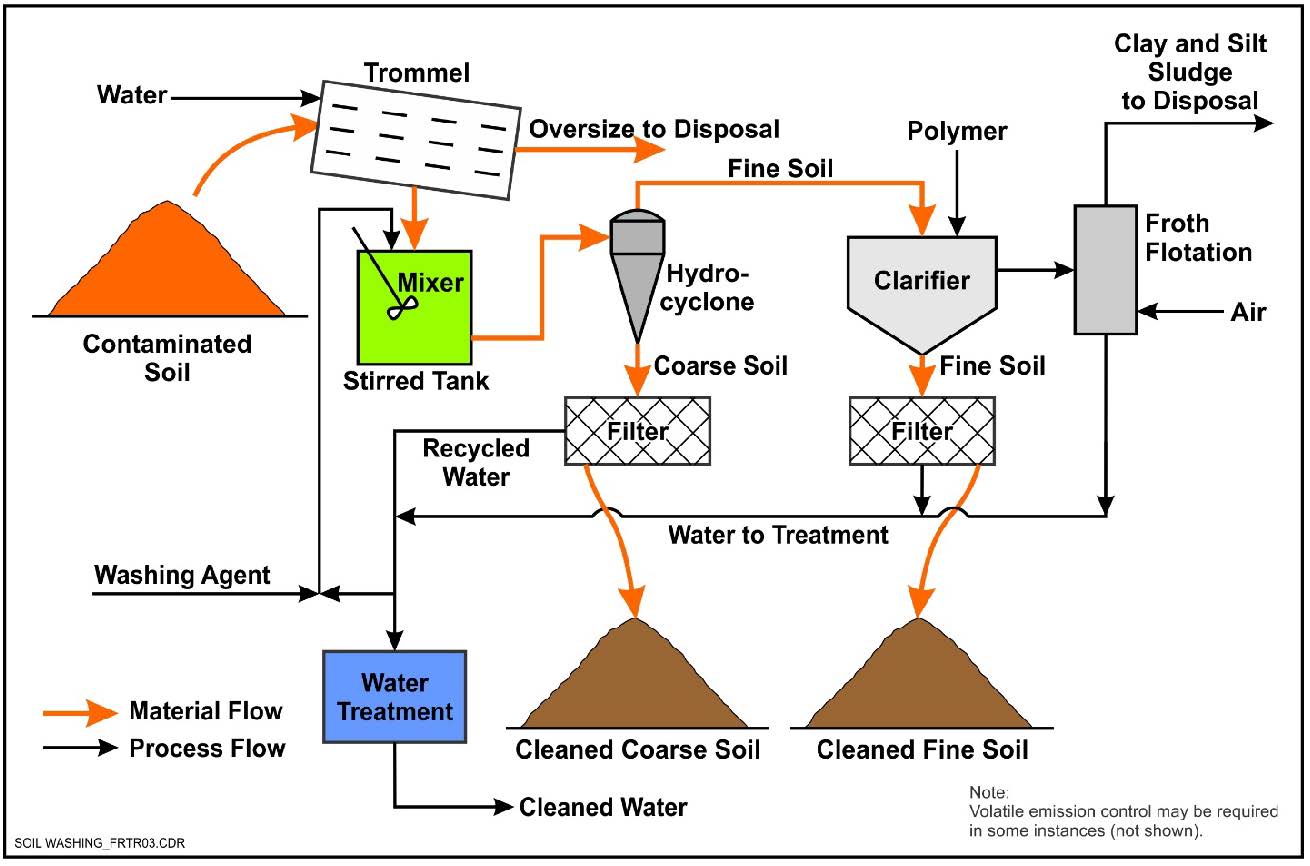

Schematic

This information may be reproduced without restriction as long as the source attribution is included.

Soil Washing

Introduction

Soil washing is an ex situ process that reduces the volume of contaminated material that must be further treated or disposed. Soil washing systems operate on the principal that most contaminants of concern (COCs) bind to the finer soil fraction, consisting of clays, silts, and fine organic matter as opposed to the larger sand and gravel fraction. Hence, soil washing systems utilize a wash solution, usually consisting of water, surfactant, and/or leaching agent, to extract and concentrate COCs as well as assist in physical size separation of the finer particles from the larger particle bulk material, thereby concentrating and reducing the contaminated material that must be disposed or further treated. Soil washing can be used either as a stand-alone technology or as the first step of a treatment train to reduce the mass of material requiring treatment by another, generally more costly technology, such as incineration.

Other Technology Names

Soil scrubbing

Description

Soil washing is generally considered a media transfer technology. It is based on mineralogical processing techniques that remove contaminants from bulk soils in one of the following two ways:

- Concentration, which is the primary removal mechanism. The contaminated particles are concentrated into a separate smaller volume of soil through particle size separation, gravity separation, and attrition scrubbing.

- Dissolution or suspending contaminants in the wash solution is a secondary removal mechanism. However, further treatment and/or disposal of the wash solution is required.

The concept of reducing soil contamination using particle size separation works because most organic and inorganic contaminants tend to bind, either chemically or physically, to clay, silt, and organic soil particles. The silt and clay are attached to sand and gravel particles by physical processes, primarily compaction and adhesion. Washing processes that separate the fine (small) clay and silt particles from the coarser sand and gravel particles effectively separate and concentrate the contaminants into a smaller volume of soil that can be further treated or disposed (EPA, 1990).

Mass transfer of contaminants from the solid phase into the liquid phase also occurs during the wash process. This dissolution process tends to be much more significant if a contaminant is not strongly bound to soil (i.e., low distribution coefficient) and when it has a high solubility in the wash solution. The rate of dissolution can be increased when adding reagents, such as surfactants, to the wash solution.

Soil washing can be divided into six steps described as follows:

- Pretreatment of the soil is performed using screens and/or other physical separation methods to remove debris and large objects, such as rocks. In some cases, crushing of larger materials can be performed if COCs are known to be present in those materials.

- Separation of the more highly contaminated fine-grained material from the coarse material can be performed using a variety of physical separation process equipment. Coarse grained material can be removed using vibratory screens or trommels. Additional separation of the fine material can be performed using hydrocyclones or spiral classifiers that leverage differences in settling velocities of the particles. Separation based on differences in specific gravity using equipment such as jigs or sluices also may be performed to remove high specific gravity particles from low specific gravity particles such as heavy metal-containing compounds (lead, radium oxide, etc.). Although not as common, in some cases, magnetic drums and magnetic separators can be used to separate materials having different magnetic susceptibilities.

- Coarse grain treatment may be required to remove COCs from the larger fraction of the separated material. However, the coarse material generally will have much lower concentrations of the COCs than the fine grain material, and therefore treatment is not always required. The most common type of treatment is attrition scrubbing1 or high-pressure wash sprays, which are used to remove contaminant films from coarser particles. Further treatment, including the addition of acids, bases, surfactants, solvents and specialized reagents to the wash solution, could be required depending on the nature and concentration of the COCs and the required treatment endpoint. The clean, larger fraction can be returned to the site for reuse after testing.

- Fine grain treatment may be performed to remove high concentrations of COCs from the fine-grained material. Various surfactants, solvents, and acids and bases may be added to the wash solution to facilitate separation. Biodegradable surfactants, comprised of various terpenes, such as limonene, can be used to facilitate separation, and alleviate subsequent water treatment requirements. Complex mixtures of contaminants in the soil (such as a mixture of metals, nonvolatile organics, and semi-volatile organic compounds [SVOCs]) and heterogeneous contaminant compositions throughout the soil mixture can make it difficult to formulate a single suitable washing solution that will consistently and reliably remove the different types of contaminants. At these sites, sequential washing, using different wash formulations and/or different soil to wash fluid ratios, may be required.

- Process water treatment is performed to remove fine materials and COCs from the water prior to disposal. The contaminated water generated from soil washing is treated with an appropriate technology(s) based on the types and concentrations of contaminants present. A wide range of water treatment options are available and multiple operations as part of a treatment train may be required. Treatment may include sand filters, coagulation and flocculation and/or dissolved air flotation performed to remove fines and some COCs. Hydrophobic clay may be used to remove light non-aqueous phase liquids. Further treatment of the water may be performed using granular activated carbon or air stripping. The specific type and sequence of treatment required is based on disposal requirements and types and concentrations of COCs present in the water stream.

- Residuals management consists of the treatment and/or disposal of the fine grain sediment that likely will contain high concentrations of COCs. Often, these residuals are dewatered using filter presses or other dewatering equipment and disposed of in a hazardous or nonhazardous landfill. Additional treatment including thermal desorption, incineration, composting, landfarming, solidification/stabilization, and others can be performed (on site or off site), depending on the nature and extent of contaminants.

Laboratory testing for geotechnical and chemical parameters should be performed on soil samples. Grain size, settling velocity, and surface chemical properties should be analyzed prior to designing and implementing a full-scale system. In addition, bench-scale tests may be performed to evaluate the best method to separate the soil and determine resulting concentrations of COCs within each size fraction. Various solvents and surfactants also can be tested on the soil to determine appropriate types and concentrations based on physical and chemical properties of the soil.

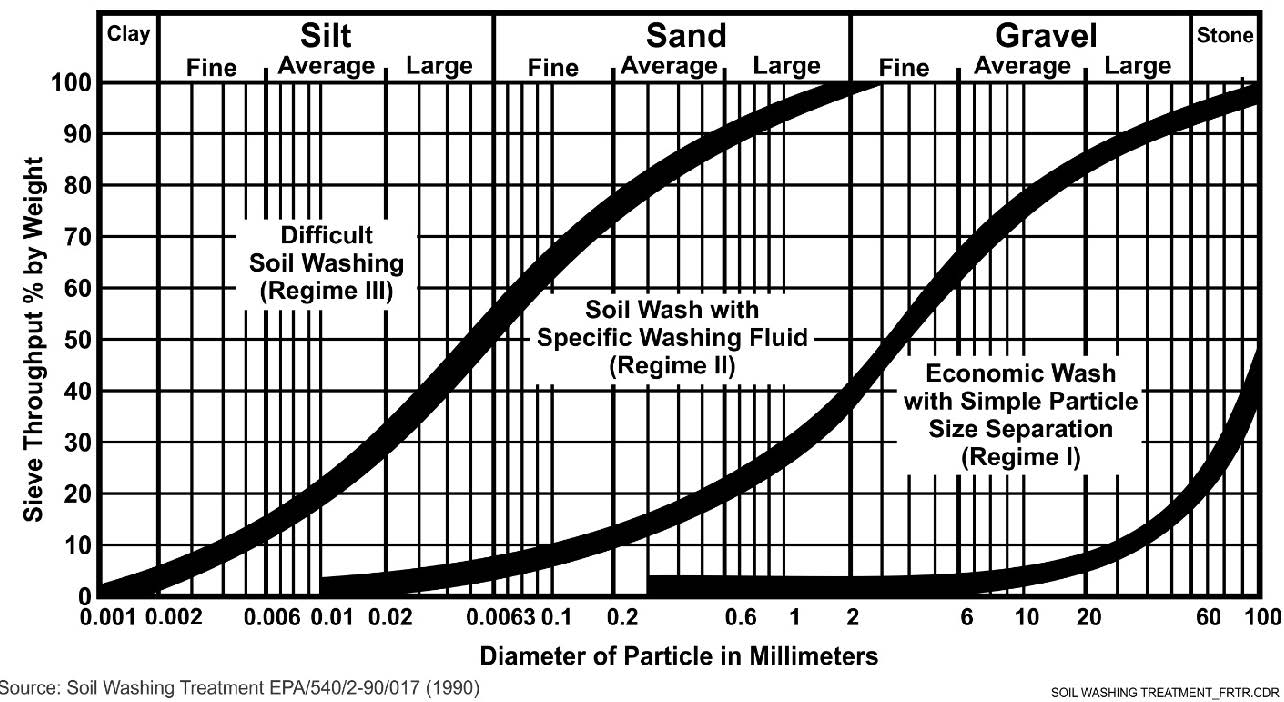

One of the most important parameters for determining the feasibility of soil washing at a site is particle size distribution. Soils comprised of coarse material are easier to separate than those consisting of fine-grained material. The figure below shows the applicability of soil washing for various particle size distributions (EPA, 1990). The majority of soils fall within Regime II, shown in the center of the figure, and are amenable to soil washing.

Soil washing commonly is performed on site using portable equipment, but also may be performed off site at a stationary facility in some cases. However, additional cost to transport the large volume of untreated material will be incurred.

Soil Washing Applicability as a function of Particle Size Distribution

Development and Implementation Status

The following checklist provides a summary of the development and implementation status of soil washing:

☐At the laboratory/bench scale and shows promise

☐In pilot studies

☒At full scale

☐To remediate an entire site (source and plume)

☒To remediate a source only

☒As part of a technology train

☐As the final remedy at multiple sites

☐To successfully attain cleanup goals in multiple sites

Soil washing is available through the following vendors:

☒Commercially available nationwide

☐Commercially available through limited vendors because of licensing or specialized equipment

☐Research organizations and academia

Applicability

|

Contaminant Class Applicability Rating for Soil Washing (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness, I/D Insufficient Data, N/A Not Applicable) | ||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| ● | ● | ● | ● | ● | ● | ● | ● | I/D |

Soil washing has been demonstrated to effectively treat soils containing a wide-range of contaminants including volatile organic compounds (VOCs), SVOCs, fuels, inorganics, radionuclides, and munitions constituents. Effectiveness is dependent on the specific COCs within a class of contaminants because it is more difficult to remove contaminants that have a greater affinity (sorption capacity) for soil. For example, VOCs are often easily removed by soil washing, with a 90 to 99% efficiency or greater. SVOCs may be removed with efficiencies of 40 to 90% by selection of the proper surfactant. Metals and pesticides, which are more insoluble in water, often require acids or chelating agents for successful soil washing (EPA, 1990).

Physical properties of the soil also impact the effectiveness of soil washing. Particles with >2 mm size distribution will require oversize pretreatment. Particles with a size distribution of 0.25 to 2 mm can be effectively washed. Particles with a size distribution of 0.063 to 0.025 mm have limited ability to be washed, while particles with a size distribution <0.063 mm (clay and silt fraction) are difficult to wash.

The volume of washed soil that must be further treated and disposed will be greater for soils that have a higher content of fine particles, including silts and clays, than those that contain more sand and gravel. Sequential washing, using different wash formulations and/or different soil to wash fluid ratios, may be required to address a complex mixture of contaminants in the soil (such as a mixture of metals, nonvolatile organics, and SVOCs).

Cost

Soil washing is an aggressive ex situ technology that is used to reduce the volume of material that must be further treated and/or disposed following excavation. The cost of soil washing is dependent on a number of factors including the size of the required equipment and desired concentration endpoints of the COCs in soil. Major cost drivers (excluding excavation) include:

Upfront Costs

- Physical and chemical characteristics of the contaminated soil including grain size and types and concentrations of COCs, which will impact the type of treatment required to achieve project goals.

- Complex waste mixtures (e.g., metals with organics) may require different wash solutions and substantially increase the type and cost of equipment and treatment.

- The volume of material requiring treatment and timeframe for treatment, which will impact the size of the required equipment.

- Complexity of water treatment equipment to treat the wash solution.

Operation and Maintenance Costs

- Types and volumes of reagents required to perform separation, which are influenced by the physical properties of the soil and the types and mixture of COCs in the soil.

- The separation, treatment and reuse of wash fluids from treated media.

- The percentage of silt and clay fines in the soil. A greater percentage of fines results in higher operating costs due to more complex treatment requiring various reagents and multiple separation steps, and results in a greater volume of material that must be disposed or further treated. If a substantial volume reduction cannot be achieved, subsequent treatment and/or disposal costs will not be reduced enough to offset the additional costs incurred by the soil washing process.

- Treatment and disposal of water treatment media, which can include spent carbon, hydrophobic clay, and sludges from chemical coagulation, flocculation, and dissolved phase flotation systems.

The list above highlights those cost dependencies specific to soil washing and does not consider the dependencies that are general to most ex situ remediation technologies. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be obtained using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

Soil washing is a short- to medium-term treatment technology expected to require weeks to months to treat the contaminated media. Treatment duration is based on the size of the system and achievable flowrates. Treatment duration is longer for complex systems that incorporate multiple separation steps and/or require separation of various size fractions of fine particles than those that do not. Treatment rates vary depending on the physical properties of the soil and types of contaminants present, but rates greater than 100 cubic yards per day can be achieved (U.S. EPA, 1996).

Implementability Considerations

The following are key considerations associated with applying soil washing:

- Contaminants in soils containing a large fraction of clay and silts may not be treated effectively using soil washing, and additional or alternative treatment may be required.

- Heterogeneous contaminant compositions throughout the soil mixture make it difficult to formulate a single suitable washing solution that will consistently and reliably remove all of the different types of contaminants.

- Soil, including the large grain size fractions, may retain low levels of COCs after washing. Samples should be analyzed for COCs to ensure that concentrations are acceptable for the planned end use of the material.

- High humic content in soil may require pretreatment.

- The wash water can be recycled, but will require treatment prior to disposal and demobilization. Additional treatment steps may be required to address hazardous levels of washing solvent remaining in the treated residuals, sludge or wastewater.

- It may be difficult to remove organics adsorbed onto clay-size particles.

- Complex waste mixtures (e.g., multiple contaminant classes in the soil) increase the difficulty of formulating a wash solution, thus sequential washing steps may be needed. Frequent changes in the wash formulation and/or the soil/wash fluid ratio may be required (ref EPA 540/2-90/017).

Resources

American Academy of Environmental Engineers. Innovative Site Remediation Technologies: Design and Application, Vol. 3: Liquid Extraction Technologies Soil Washing, Soil Flushing, Solvent/Chemical. (1998) (PDF)(472 pp, 33 MB)

This book describes the design, application, and implementation of soil washing, soil flushing, and chemical extraction technologies for metals and organics.

Battelle. Physical Separation and Acid Leaching: A Demonstration of Small-Arms Range Remediation at Fort Polk, Louisiana. (1998) (PDF)(51 pp, 1.7 MB)

This technology application analysis report prepared for Naval Facilities Engineering Service Center (NFESC) and U.S. Army Environmental Center describes the application of an acid leaching soil washing process to remove lead contamination from soil.

CL:aire. Understanding Soil Washing (2007) (PDF)(4 pp, 0.2 MB)

This technical bulletin provides an overview of soil washing to treat contaminated soil.

EPA. Soil Washing Treatment (1990) (PDF)(10 pp, 0.6 MB)

This engineering bulletin describes soil washing, its technical applicability and limitations to treat soil contaminated with a range of environmental contaminants.

EPA. A Citizens Guide to Soil Washing (1996) (PDF)(4 pp, 0.2 MB)

A fact sheet intended for public guidance on the method of soil washing to clean up pollution at Superfund and other sites.

USACE. Soil Washing through Separation/Solubilization: Guide Specifications for Construction. (2010) (PDF)(34 pp, 0.2 MB)

This specification provides guidance for requirements for removal of heavy metals/inorganics, organics, and radioactive wastes by water-based soil washing.