Groundwater Pump and Treat

On this page:

- Schematic

- Introduction

- Other Technology Names

- Description

- Development Status

- Applicability

- Cost

- Duration

- Implementability Considerations

- Resources

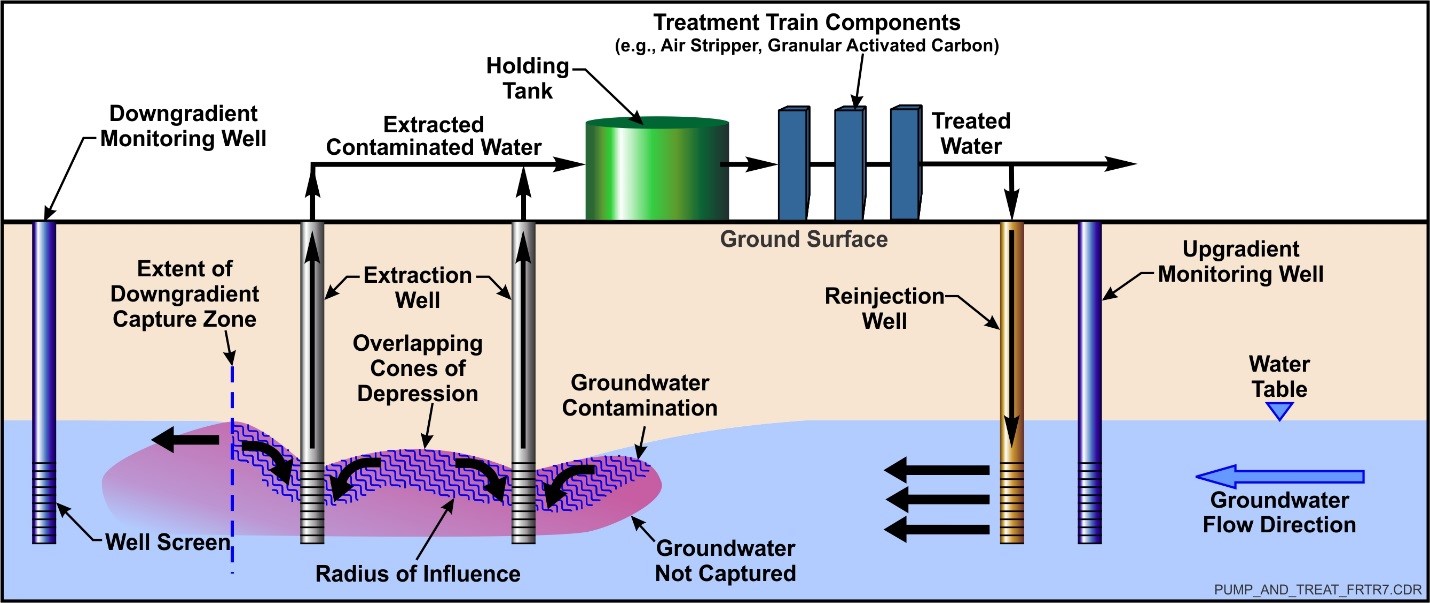

Schematic

This information may be reproduced without restriction as long as the source attribution is included.

Groundwater Pump and Treat

Introduction

Contaminated groundwater and/or non-aqueous phase liquid (NAPL) can be pumped from the subsurface, treated above ground, and discharged. Pump and treat technology is focused on managing plume migration, but is sometimes used for contaminant mass removal. In some cases, it is intended to control groundwater mounding and movement associated with other treatment technologies, such as containment barriers.

Other Technology Names

Groundwater Extraction and Treatment

Description

Pump and treat technology involves the retrieval of groundwater and/or NAPL from a contaminated aquifer using one or more extraction wells, trenches, or galleries, and treating the water in an above-ground treatment system prior to discharge. Above-ground treatment of extracted groundwater/NAPL often includes multiple technologies used in a treatment train. Treated groundwater can be reinjected into the subsurface, discharged to a publicly owned treatment works (POTW), discharged to a receiving surface water body either directly or through a storm drain system upon receipt of regulatory agency concurrence, or beneficially reused (e.g., as irrigation water).

An up-to-date conceptual site model (CSM) should be developed prior to designing a pump and treat system. Site-specific data regarding aquifer and contaminant characteristics required to design the system components, include:

- Contaminant type, area, and volume, namely the contaminant plume in three dimensions must be determined prior to designing the system.

- Capture zone analysis should be performed to determine appropriate capture zones based on groundwater flow pattern and contaminant distribution, migration pathways, and preferential pathways, as well as applicable regulatory criteria

- Vertical wells, horizontal wells, recovery trenches or galleries. Locations, quantity, depth, diameter, screen perforation size, filter pack type and grading, construction materials, and material compatibility with the site contaminants or other treatment technologies in use (e.g., electrical resistance soil heating) must be determined.

- Number and types of extraction pumps, either submersible or above-ground.

- Treatment train components, for example, air strippers and/or granular activated carbon (GAC) filters, and design of piping, instrumentation, and control systems, including programmable logic controller for system operation.

- Treatment system compound, for example, building or trailer that houses system equipment and associated structural, mechanical, and electrical components.

- Location and permitting of a point of discharge for treated water. The selected point of discharge is a primary factor for establishing regulatory or other treatment criteria for the system. For example, treatment for some contaminants can be less aggressive if further treatment can be assured in a POTW receiving the water.

- A monitoring well network to verify system performance against the goals of containment and/or contaminant mass reduction.

- Treatment system influent, intermediate, and effluent sampling points to assess system efficiency and compliance with applicable discharge permit requirements.

Pump and Treat for Contaminant Mass Reduction

Pump and treat systems focused on contaminant mass reduction throughout a plume were widely installed in the 1980s and 1990s (NRC, 1994); however, performance data over the last several decades have shown that pump and treat technology is typically not an optimal choice for this purpose, except for rare sites (NRC, 1994; Navy RITS, 2018). Because of the tendency of many contaminants to sorb to the heterogeneous soil types making up a typical aquifer, the contaminant mass recovered by a pump and treat system can quickly become limited by the slow pace of contaminant back-diffusion from soil into groundwater.

When applied to distal dilute, dissolved-phase plumes in permeable materials, pump and treat can effectively reduce the footprint of the plume. Significant contaminant mass reduction may also be achieved for more homogeneous and transmissive aquifer units (i.e., contaminant mass contacted by large number of pore volume flushes). Particularly when both extraction and injection are applied to substantially increase flushing through the aquifer, the response can be relatively quick. Such reductions can significantly reduce exposure risks. In addition, highly focused extraction and injection can reduce concentrations in source areas containing residual NAPL in a reduced timeframe, though the economic efficiency of this is very site specific.

Pump and treat can be used to enhance NAPL recovery in the source area. Information regarding NAPL recovery is provided in the free product recovery technology profiles. In addition, multiphase extraction, a specialized form of enhanced pump and treat that increases LNAPL recovery, promotes biodegradation of hydrocarbons in the vadose zone, and recovers contaminated soil gas while minimizing groundwater extraction, is described here.

The primary purpose of applying pump and treat systems for source control is to intercept and capture dissolved phase contamination from the saturated zone in the source area. With this source control measure, the downgradient dissolved phase plume will be cut off from the source area. Capture of the contaminants in the source area will allow the downgradient plume to diminish (PNNL, 2015)

Pump and Treat for Groundwater and Contaminant Flux Control and Plume Containment

Pump and treat systems can be installed for the purpose of controlling contaminated groundwater mounding and migration, or for reducing the contaminant flux rate from a source area. Pumping from a groundwater well creates a cone of depression around the well, and a resulting roughly parabolic capture zone. Groundwater flowing from upgradient of the well is captured, as is some groundwater in side- and down-gradient directions from the extraction well. The size and shape of the capture zone is dependent on the aquifer characteristics and the design and operating characteristics of the extraction well. Groups of wells, or recovery trenches and galleries, generate overlapping or elongated capture zones, which can be designed to achieve coverage of a contaminant plume or hotspot (high concentration zone of contaminants). Trenches and horizontal wells are sometimes used to recover contaminants from thin, isolated, higher permeability zones. The capture zones and cones of depression can also be designed to maintain a water level required by a companion remediation technology, such as the prevention of mounding behind a containment barrier or exposure of the capillary smear zone for volatilization by soil vapor extraction. Capture zones can also be designed such that the extraction well or well network itself becomes a barrier to contaminated groundwater flow, preventing contaminant migration beyond the downgradient influence of the capture zone. The goal of plume containment is to diminish the downgradient plume so that receptors are protected.

Other Uses of Pumping at Contaminated Sites

Other uses of pump and treat systems include increasing the hydraulic gradient to improve contaminant recovery, recovery and reuse of an injectate, or groundwater recirculation to flush water through residual source areas or enhance the distribution of in situ treatment amendments (e.g., chemical oxidant or carbon substrate) in the subsurface. An example of recovery and reuse of injectate is use of surfactants (i.e., soil flushing) to facilitate remediation of sites contaminated with semi-volatile organic compounds (SVOCs). Surfactants are injected in the contaminated zone, recovered with contaminated groundwater, and are separated and reused to increase the economic feasibility of the technology.

Treatment of Extracted Groundwater/NAPL

The contaminant type, its concentration levels, and the extraction flow rates influence above-ground treatment options and design. For mixed streams of groundwater and NAPL, often the first component of the treatment train is an oil/water separator, or equivalent separation technology. The recovered NAPL is routed to a storage vessel for off-site transport and disposal or recycling, unless there is an on-site process that can reuse the material. The separated groundwater containing dissolved contaminants can then be routed through one or more water treatment components, such as air stripping or liquid phase granular activated carbon (GAC) to reduce the contaminant concentrations to levels meeting applicable regulatory criteria for discharge to storm sewer or POTW. Additional treatment train components may be necessary if the extracted groundwater contains inorganics that exceed the regulatory discharge criteria. In some instances, the extracted groundwater must be pre-treated (e.g., particulate and/or iron and manganese removal) to prevent or reduce the potential for clogging downstream piping and treatment equipment and increase the operational efficiency of other treatment processes, e.g., GAC and air stripping units.

Disposal

Treated groundwater can be reinjected into the subsurface, discharged to a POTW or to a receiving surface water body either directly or through a storm drain system, or beneficially reused (e.g., as irrigation water), upon regulatory agency approval. Reinjection may require a state permit, 1 and a demonstration that the water will be captured by the pump and treat system and will not push contaminated water from the treatment area, may be required. Oftentimes, reinjection is used to constrain the plume boundary and flush contaminants toward the recovery wells. POTW discharge can sometimes allow for higher regulatory discharge criteria; however, some POTWs do not have the capacity to receive relatively clean water, and typically charge a fee per 100 cubic feet of water discharged. Discharge to a storm drain or directly to a receiving water body typically requires a National Pollution Discharge Elimination System (NPDES) permit, and may not be approved if other discharge options are available. Some sites may offer an opportunity for beneficial reuse of treated water, such as for irrigation of agriculture. Treated water also may be used for public water supply, and existing municipal wells may be incorporated into the overall recovery strategy.

System Performance Monitoring and Termination Decision

Pump and treat systems require monitoring of the system itself to potentially include:

- Influent and effluent flow rates and totalized flow, as well as flow rates of each extraction (and injection) well.

- Contaminant concentrations in influent (from each well), intermediate (between treatment vessels), and effluent water. Resulting data may be used to calculate mass removal rates and trends to facilitate system optimization.

- Synoptic groundwater level survey to evaluate hydraulic gradient and capture of contaminated groundwater.

- Free product sensing, if applicable, in effluent with automatic shutdown capability.

- Water level in process tanks, pressure drop across treatment vessels (including air strippers and filtration units), and blower air flow rate for air strippers.

- Off-gas treatment system contaminant concentrations (influent, intermediate, and effluent), flow rates and pressures, if emission controls are required.

Periodic groundwater sampling of the monitoring well network is typically required to demonstrate on-going system performance, evaluate contaminant concentration reduction trends, and attain hydraulic capture/migration control of the plume. Monitoring wells can be placed within a plume to monitor changes in contaminant concentrations and demonstrate hydraulic plume capture, or at the plume's horizontal and vertical boundaries to demonstrate ongoing containment. In some cases, sentinel wells are located between the plume boundary and downgradient receptors to allow an early warning of loss of plume containment.

The monitoring plan for a pump and treat system should be based on site-specific remedial objectives. For decision-making purposes and to gain concurrence by all stakeholders, clear metrics should be developed early in the remediation life cycle as part of an overall adaptive site management strategy that allows for termination of system operation (ITRC, 2107). These metrics should be subject to continuing evaluation and modification throughout the remediation life cycle as needed. These interim or final metrics can represent the attainment of the site remediation objectives and cleanup levels, achievement of some type of defined asymptotic plateau condition where continued operation would not provide continued beneficial contaminant mass removal, or represent a pre-determined level where natural attenuation (or an alternative treatment train technology) is capable of attaining the cleanup levels within a reasonably comparable timeframe. Attainment of the defined interim metric milestone should trigger shutting down the pump and treat system and transitioning to a different remedy component that has been defined in a work plan and agreed to by all stakeholders (e.g., alternative treatment train technology or natural attenuation).

Monitoring data also are used to optimize the extraction well network to improve recovery and maintain efficient mass removal and treatment plant operation. Pre-mature asymptotic contaminant mass removal levels by the treatment system may indicate the need for optimization of the pumping wells and/or treatment processes to improve mass removal by the system.

Development Status and Availability

The following checklist provides a summary of the development and implementation status of pump and treat:

☐ At the laboratory/bench scale and shows promise

☐ In pilot studies

☒ At full scale

☒ To remediate an entire site (source and plume)

☒ To remediate a source only

☒ As part of a technology train

☒ As the final remedy at multiple sites

☒ To successfully attain cleanup goals in multiple sites

Pump and treat is available through the following vendors:

☒ Commercially available nationwide

☐ Commercially available through limited vendors because of licensing or specialized equipment

☐ Research organizations and academia

Applicability

|

Contaminant Class Applicability Rating for Pump and Treat (Rating codes: Demonstrated Effectiveness, ◐ Limited Effectiveness, No Demonstrated Effectiveness I/D Insufficient Data, N/A Not Applicable) | ||||||||

|---|---|---|---|---|---|---|---|---|

Nonhalogenated VOC |

Halogenated VOC |

Nonhalogenated SVOC |

Halogenated SVOC |

Fuels |

Inorganics |

Radionuclides |

Munitions |

Emerging Contaminants |

| ● | ● | ● | ● | ● | ● | ● | ● | ● |

Pump and treat technology is applicable to the complete range of contaminant groups that have higher water solubilities with no particular target group. Historically, pump and treat systems have been used frequently to treat plumes contaminated with NAPLs and associated dissolved-phase contamination including volatile organic compounds (VOCs), such as benzene, toluene, ethylbenzene, and total xylenes (BTEX), methyl tertiary butyl ether (MTBE), halogenated VOCs (e.g., trichloroethene and its daughter products) and SVOCs such as naphthalene. Recovery is more effective for those contaminants that are more soluble in water and/or have less affinity for the soil matrix. Contaminants that are insoluble or have very low solubilities in water cannot be recovered and treated using this technology. The type of contaminant and its concentration and discharge limits will dictate above-ground treatment requirements.

Cost

The upfront costs for pump and treat technology can be high compared to other remediation or in situ treatment technologies. Lifetime costs for operation and maintenance (O&M) of pump and treat systems are high when slow back diffusion of contaminants is encountered which can result in very long timeframes to meet cleanup levels, and therefore alternative remedies should be considered. Major cost drivers include:

Upfront Costs

- Sufficiently detailed characterization of the aquifer and contaminant characteristics must be performed to allow design of the pumping component and the treatment component. An inadequate conceptual site model can lead to an ineffective design and application and unreasonable remediation timeframe.

- Pump tests and associated modeling to estimate operating parameters and capture influence, demonstrate the expected performance of the system, and optimize the design.

- Treatment system equipment, which is dictated by the design pumping flow rate that determines the sizing of treatment system equipment and system compound, as well as the expected influent concentrations.

- System compound structural, mechanical, and electrical components, and associated design and construction.

- Sampling and analysis to characterize the influent stream and demonstrate compliance with discharge requirements.

- Presence or absence of NAPL, which requires separation and disposal.

- Well/trench installation (e.g., above or below grade, distances, topography), with cost dependent on number and depth of wells, depth and length of trenching, and design specifics.

- Piping and control system costs (e.g., programmable logic controller and supervisory control and data acquisition [SCADA] systems), with the potential need for remote telemetry.

- Need for double-wall piping and related leak detection controls/instrumentation.

- Need for pre-treatment system(s) (e.g., metals precipitation or suspended solids filtration).

- Need for off-gas emission control, if air strippers are used.

- Use of recovery trenches and horizontal wells, which are useful for targeting contaminant removal from thin, isolated, higher permeability zones acting as preferred pathways. Trenches/horizontal wells have a greater lateral influence of recovery, so installation costs to impact the same amount of aquifer may be lower than with vertical well arrays.

Operation and Maintenance Costs

- Required on-site operator presence.

- Replacement and regeneration of sorptive media (e.g., GAC) and consumable chemicals used in treatment).

- Optimization of recovery system to maximize efficiency of recovery wells and the treatment plant. Pumping from recovery wells may need to be alternated periodically to maintain high mass recovery.

- Type and volume of NAPL recovered and disposed.

- Regular maintenance and replacement of pumps, blowers, filters, pressure and flow meters, GAC and/or air stripper trays, and other mechanical equipment.

- Process monitoring associated with the treatment system and controls (including needed replacement parts and upgrades).

- Degree of fouling and corresponding maintenance, including extraction well redevelopment and possibly even ultimate replacement.

- Periodic sampling of groundwater monitoring well network and treatment system influent and effluent.

- On-going labor, materials, and power costs and other utilities.

- On-going discharge fees.

The list above highlights those cost dependencies specific to pump and treat and does not consider the dependencies that are general to most remediation technologies. Click here for a general discussion on costing which includes definitions and repetitive costs for remediation technologies. A project-specific cost estimate can be obtained using an integrated cost-estimating application such as RACER® or consulting with a subject matter expert.

Duration

Pump and treat generally is a long-term treatment technology. Durations of pump and treat actions vary widely, depending on factors including the remedial action objectives and cleanup goals and the nature and distribution of contaminants. Pump and treat systems focused on mass reduction for dissolved contaminants can operate for multiple decades. Systems installed to target a plume containment remedy must operate for the life of the containment. Systems installed to prevent migration of a plume must operate until other technologies, or natural attenuation, reduce the contaminant concentrations to below the cleanup level. Sites with complex geology (e.g., heterogeneity or fractured flow) typically have the longest operational timeframes for pump and treat systems.

Shorter duration pump and treat systems can be used to achieve an alternative remedial objective other than aquifer restoration to drinking water standards. For example, pumping can be focused on reducing mobile NAPL to a specified rate of recovery or to reduce the NAPL migration potential, after which other treatment technologies can be used.

Implementability Considerations

The following are key considerations associated with implementing pump and treat technology:

- Design of extraction and treatment systems should be based on longer duration field pump or pilot tests as opposed to engineering estimates or "worst-case" projections, which can lead to inaccurate input data and over-design of treatment equipment.

- Heterogeneity and transmissivity of the aquifer will influence the production rate and capture influence, propensity for prolonged back-diffusion of contaminants from fine-grained soil types, and potential for preferential migration pathways. Detailed logging of stratigraphy to facilitate evaluation of lithologic influences on the distribution and mobility of site contaminants and impacts of the pump and treat system on them should be performed.

- Lateral and vertical extent of the plume will dictate the placement of extraction wells or trenches, and the length of piping and power runs needed to move water to a centralized treatment plant.

- The nature and mixture of the contaminant(s) will dictate the need for multiple treatment processes in the treatment train to address all contaminants.

- The presence of surface water bodies could be affected by (inadvertent dewatering of a wetland) or could affect the treatment system (e.g., drawing in saline water from a marine water body).

- Whether the plume has migrated off site may require the pursuit of access agreements and need for the installation of additional transfer piping or monitoring/extraction wells.

- Depending on plume size and complexity, the extraction well layout may require periodic optimization, which may include installing new wells, or allowing for transition to in situ treatment technologies in parts of the plume exhibiting reduced or lower than expected levels of contaminant mass recovery.

- Initial well installation should be followed by determination of the baseline yield for each well. Periodic measurements of well yield should be performed to identify the need for well rehabilitation efforts prior to reaching levels of poor performance that may not be recoverable.

- Well re-development must be properly performed for a sufficient period of time to maximize yield instead of just targeting a minimum number of well volumes as is often done for monitoring wells.

- Options and locations for water discharge and associated costs must be evaluated early in the design process to verify the availability of a reasonable cost option.

- Required permits for treated groundwater discharge, or recharge into the aquifer and need for air stripper off-gas treatment must be determined early in the design process.

- Mineral precipitation (e.g., iron) and biological fouling can occur at some sites, which may require rehabilitation and redevelopment of extraction wells and/or inclusion of costly pretreatment systems and maintenance of system conveyance piping and above-ground treatment equipment.

- It is critical that the pump and treat system design provide adequate flexibility to allow modification of amount and location of pumping to adjust for changing conditions with time, including the plume footprint or axis location and decreasing contaminant levels. Treatment systems should also be designed for future flexibility/adjustments based on the need to increase the treatment system capacity, the addition of treatment processes, as well as decreasing contaminant concentrations that will occur over time (e.g., inclusion of extra floor space, use of variable frequency drive motors).

Resources

EPA. Pump-and-Treat Ground-Water Remediation. A Guide for Decision Makers and Practitioners (1996) (PDF) (90 pp, 2.76 MB)

This guide provides an introduction to pump and treat remediation, from the perspective of a time when pump and treat was a widely used treatment technology.

EPA. Ground Water Issue: Design Guidelines for Conventional Pump-and-Treat Systems (1997) (PDF) (38 pp, 1.19 MB)

This issue paper focuses on design of conventional groundwater extraction and injection systems used in subsurface remediation.

EPA. Elements for Effective Management of Operating Pump and Treat Systems (2002) (PDF) (22 pp, 436 KB)

This fact sheet summarizes key aspects of effective management for operating pump and treat systems based on lessons learned from conducting optimization evaluations at 20 Superfund-financed systems.

EPA. Options for Discharging Treated Water from Pump and Treat Systems (2007) (PDF) (23 pp, 347 KB)

This fact sheet provides potential options for discharging treated water from pump and treat systems.

EPA. Optimization Strategies for Long-Term Ground Water Remedies (with emphasis on pump and treat systems) (2007) (PDF) (33 pp, 340 KB)

This fact sheet describes the principles and techniques for optimizing long-term groundwater remedies, with particular emphasis on optimizing pump and treat systems.

EPA. A Systematic Approach for Evaluation of Capture Zones at Pump and Treat Systems (2008) (PDF) (166 pp, 18.5 MB)

This document describes a systematic approach for performing capture zone analysis associated with groundwater pump and treat systems.

EPA. A Citizen's Guide to Pump and Treat (2012) (PDF) (2 pp, 752 KB)

This document provides an overview of pump and treat, meant for the public.

ITRC. Remediation Management of Complex Sites (2017)

This website presents the adaptive site management concept, which is a recommended, holistic process for managing complex sites.

National Research Council. Alternatives for Ground Water Cleanup (1994)

This book, published by the Committee on Ground Water Cleanup, provides a review and assessment of the performance of pump and treat systems and the technical limitations of groundwater remediation.

Pacific Northwest National Laboratories. Performance Assessment for Pump-and-Treat Closure or Transition (2015) (PDF) (118 pp, 4.37 MB)

This document, prepared by PNNL for the Department of Energy, provides a structured approach for assessing pump and treat performance to support a decision to optimize, transition, or close a pump and treat remedy.

Truex, Michael; Johnson, Chris; Macbeth, Tamzen; Becker, Dave; Lynch, Kira; Giaudrone, Dominic; Frantz, Aaron; Lee, Hope. Performance Assessment of Pump-and-Treat Systems (2017) (PDF) (18 pp, 54.8 MB)

This article is a follow-on to the 2015 PNNL publication, providing a structured approach for assessing pump and treat performance to support a decision to optimize, transition, or close a pump and treat remedy.